Forma Robotics

@Forma_Robotics

Forma Robotics is creating the world's first decentralized Robotics-as-a-Service (RaaS) network - powered by a modular, open-source robotic arm.

Today we’re using a franka.de arm to prototype our first RaaS workflow — soon, the arm doing this will be ours. Using a Franka arm, we prototyped the pick-and-place of Forma logo, a pipeline that will run on the Forma robotic arm: • trajectory planning •…

Before we drop the next updates; including circuits, PCB work, electronics, and the upcoming CAD release - we pushed a round of small bug fixes to GitHub, related to mounting of servos. For everyone following along: robotics and hardware take time. This isn’t like spinning up a…

Cool to see the Franka setup. We’re also using Franka for the initial phase before we bring our own arm online.

Robots that can learn real-world skills in minutes instead of months are not science fiction anymore. We are watching the shift happen in front of us. The team at @ToyotaResearch has been pushing this space for years. Now their work is leaving the lab and moving into real…

Robotics isn’t magic - it’s precision. Today we had the Franka arm write ‘FORMA’ with a marker to validate our motion control and path-planning stack. When a robot can write smoothly, it can assemble smoothly. It is our way of stress-testing the precision layer before scaling to…

What’s the point of the Forma token? A lot of people ask this - and the answer is actually simple. Forma isn’t “web3 for the vibes.” We’re building real robotics, real hardware, and a global RaaS network. The token exists because it unlocks things that traditional robotics…

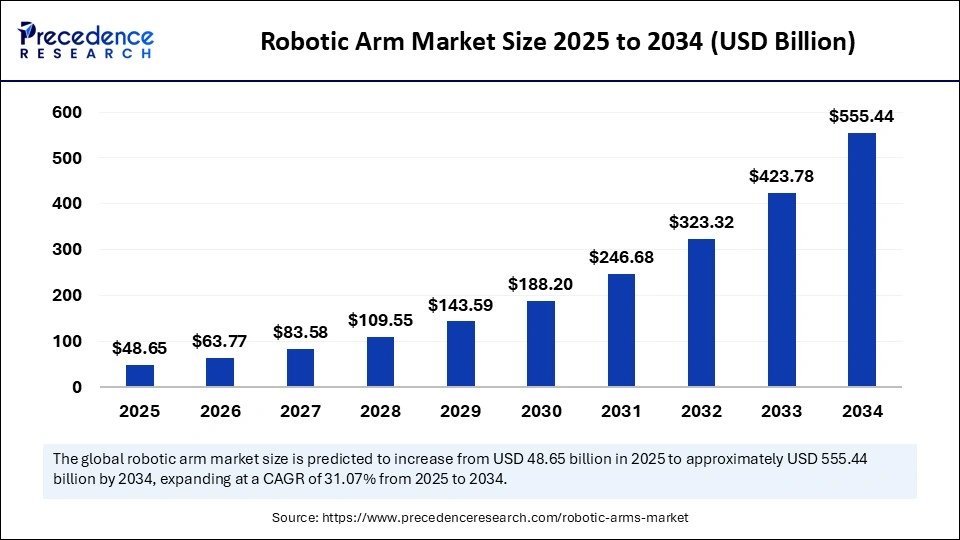

The global robotic-arm market is growing way faster than most people realize. It’s projected to surge from around $48B in 2025 to over $550B by 2034 - a huge wave driven by automation, AI, and the push for smarter, more efficient manufacturing. What’s behind it? • Industry 4.0…

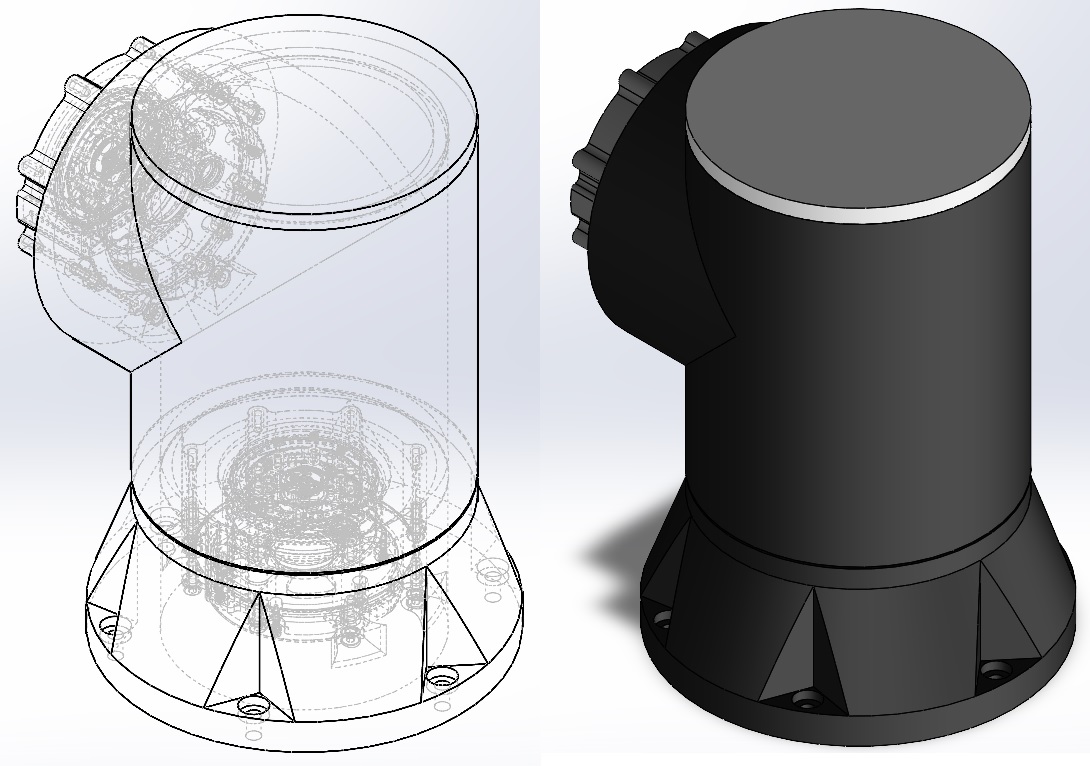

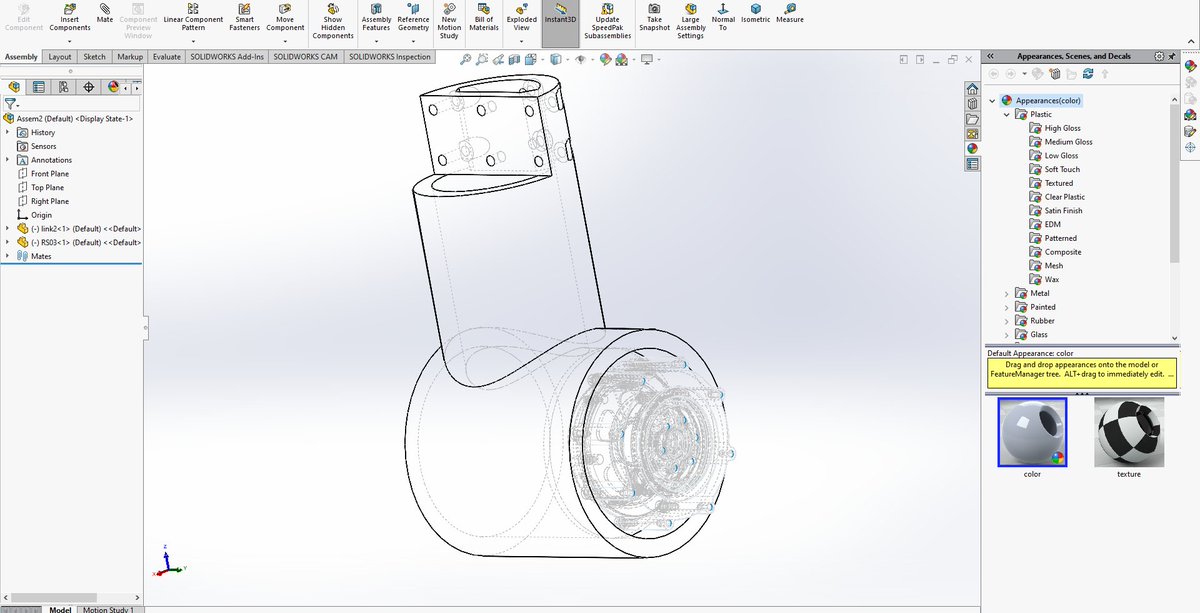

Another piece of the Forma Arm is in place. Link2 is now live on GitHub - connected to Link1 and ready for the next segment to attach halfway along its frame. Piece by piece, the Forma Arm is taking form. GitHub Link: github.com/FormaRobotics/…

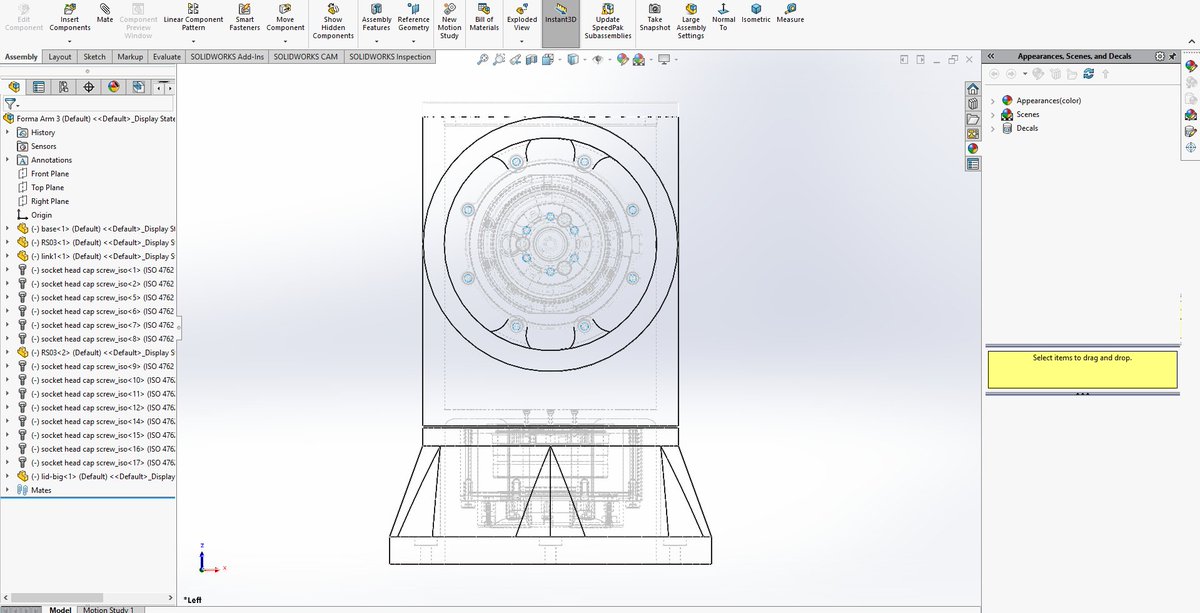

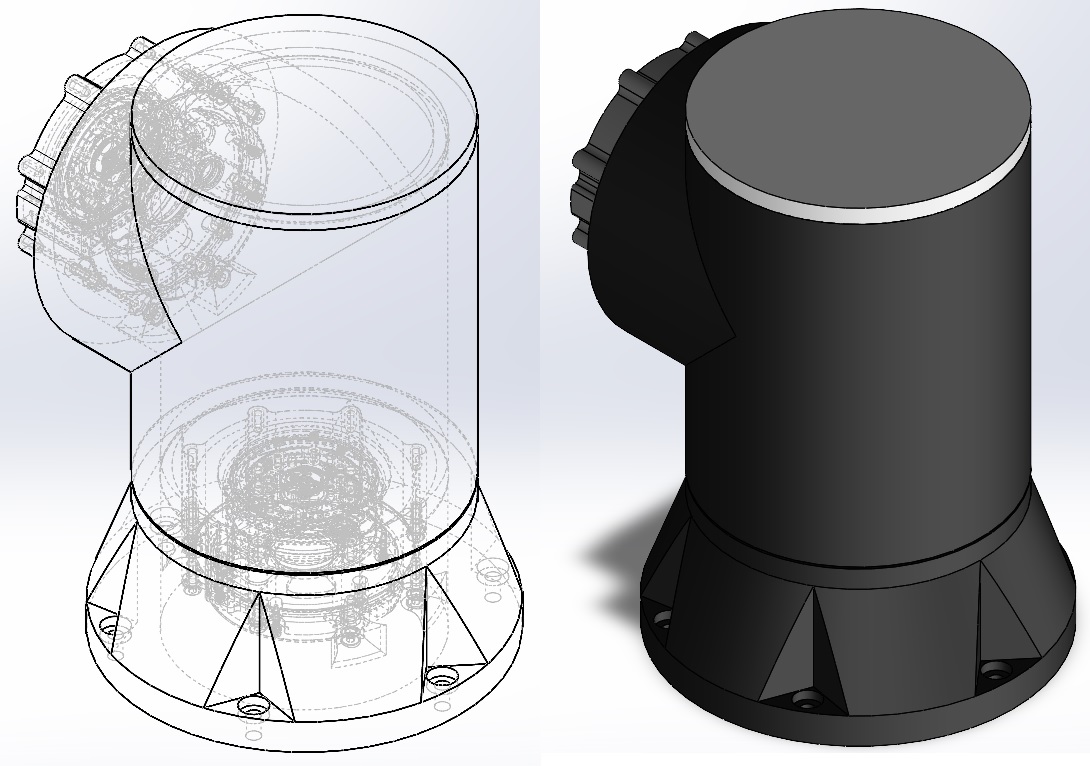

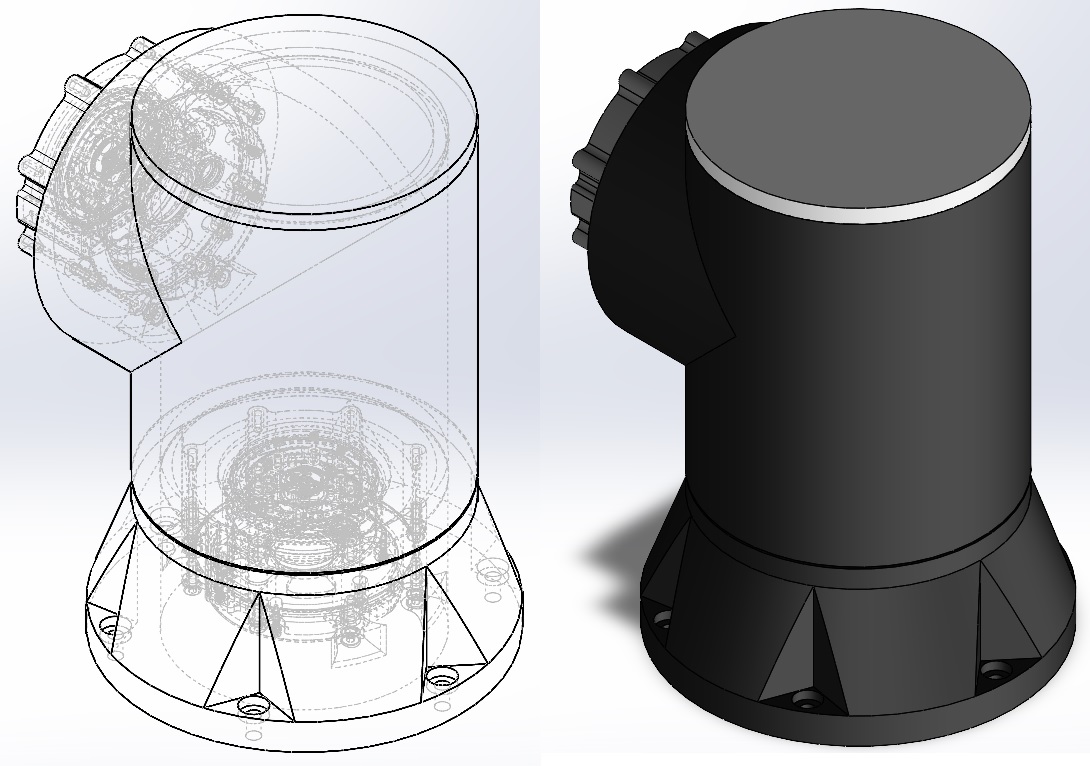

New updates just went up on GitHub. Added the first arm segment, connected to the base, along with updates to the BoM and reference documentation. GitHub Repo: github.com/FormaRobotics/… More to come.

The next segment of the Forma Arm introduces a more challenging geometry - it must connect to the next link at its midpoint. CAD files for this part will be released soon.

👀👀

The future is lights on production, bright factories

Another perspective on the assembly. The base and first link are in place, giving a glimpse of how the full arm will take form. Each part is a small step toward the full Forma Arm - designed to be modular, precise, and fully open. CAD files, BoM, and firmware are all available…

New updates just went up on GitHub. Added the first arm segment, connected to the base, along with updates to the BoM and reference documentation. GitHub Repo: github.com/FormaRobotics/… More to come.

Most servos measure the motor. These measure the joint. These actuators use dual magnetic encoders: • one on the motor rotor • one on the output shaft (after the gearbox) Most servos only measure the motor shaft and assume the gearbox output matches. But gearboxes have…

New updates just went up on GitHub. Added the first arm segment, connected to the base, along with updates to the BoM and reference documentation. GitHub Repo: github.com/FormaRobotics/… More to come.

✅👀

On November 10, join our AI Physics livestream at 9 AM PDT to learn about the latest #ML architectures for computational engineering workloads. See how NVIDIA PhysicsNemo empowers engineering teams to deploy AI-driven simulations and digital twins at scale, accelerating…

We’re building robots differently. Not as machines you script, but as systems you can teach. Instead of programming trajectories line by line, imagine showing the robot the task once — pointing to objects, defining the goal, and letting the system learn the workflow through…

Robots used to follow scripts. Move X → Rotate Y → Place Z. If anything shifted — lighting, part orientation, tolerance — the robot stopped. Humans had to fix the robot, not the other way around. At Forma, we’re flipping that relationship. Our robots learn tasks the way…

Robotics needs more doers. More experimenters. More people willing to test, break, fix, and try again. If you care about: • mechanical design • motion control • firmware • AI in physical systems You belong here. Follow along. Jump in. Help us bend the robotics learning…

United States Tendances

- 1. #AEWDynamite 16K posts

- 2. #Survivor49 2,865 posts

- 3. Donovan Mitchell 3,564 posts

- 4. #CMAawards 3,232 posts

- 5. UConn 6,975 posts

- 6. Cavs 7,913 posts

- 7. #SistasOnBET 1,524 posts

- 8. Nick Allen 1,625 posts

- 9. Dubon 2,611 posts

- 10. Arizona 31.1K posts

- 11. #cma2025 N/A

- 12. Aaron Holiday N/A

- 13. Rockets 15.3K posts

- 14. Mobley 3,951 posts

- 15. Sengun 5,167 posts

- 16. Jaden Bradley N/A

- 17. Marquette 1,937 posts

- 18. Riho 2,563 posts

- 19. Savannah 4,456 posts

- 20. FEMA 44.1K posts

Something went wrong.

Something went wrong.