Incus3D

@Incus3D

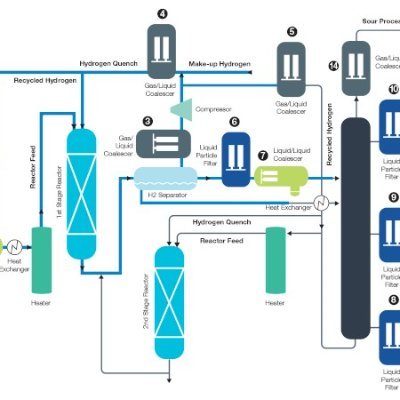

New approach to lithography-based metal additive manufacturing.

You might like

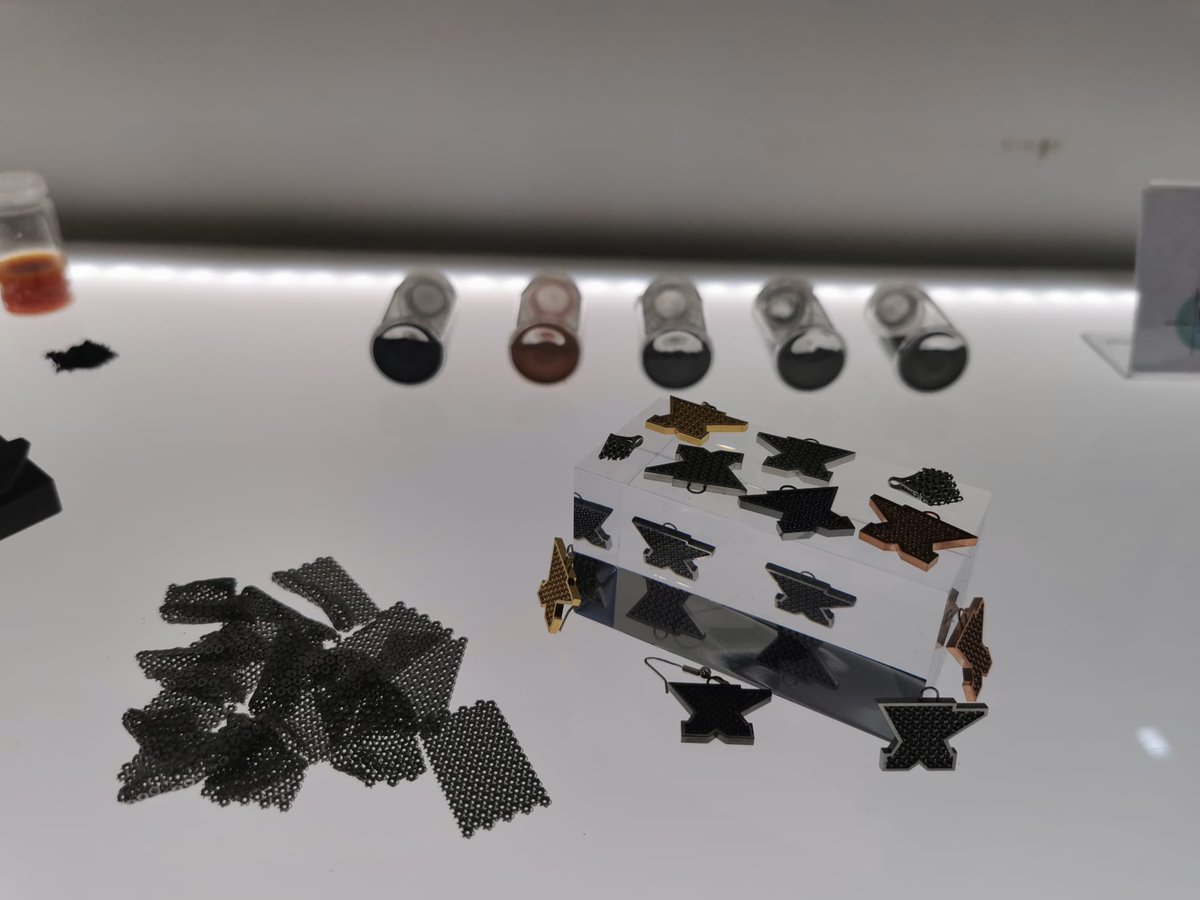

Revolutionizing Jewelry Manufacturing with LMM Technology! 🚀At #Vicenzaoro, industry leaders called LMM a game-changer for intricate, high-quality designs. With top surface quality, zero porosity, and great material efficiency, it’s shaping the future of jewelry production.

Kicking off 2025 with exciting projects, new developments, and events across Europe, the US, the Middle East, and the UK! Our redesigned #3Dprinter Hammer Evo35 delivers enhanced production and industrial performance for professional environments. Stay tuned for updates! #incus3d

We’re happy to announce our first exhibition in #India at the AMTECH Expo in Bengaluru on 11–12.12.24! Visit us at booth E12 to discover the support-free #3Dprinting process and get an up-close look at precise metal parts created using Lithography-based Metal Manufacturing.

Incus bringt den HammerEvo35 auf den Markt, eine Weiterentwicklung für präzisen Metall-3D-Druck und industrielle Anforderungen: 3d-grenzenlos.de/magazin/3d-dru… #3dprint #3dprinting #3ddruck #additivemanufacturing #additivefertigung #hammerEvo35 #incus #formnext @formnext_expo @Incus3D

3d-grenzenlos.de

Incus stellt verbesserte Version seines Hammer Evo35 Metall-3D-Druckers vor

Incus hat den Hammer Evo35 3D-Drucker vorgestellt, der für höhere Präzision und Industrieanwendungen im Metallbereich entwickelt wurde.

Only 12 days to go until @formnext_expo! We can’t wait to meet friends & partners at our booth (E59 in hall 11.1) & showcase our latest innovations in LMM technology! The rings were created by Sarto Electro Equipment's (P) Ltd., printed by Incus, and polished by POLITECHNO.

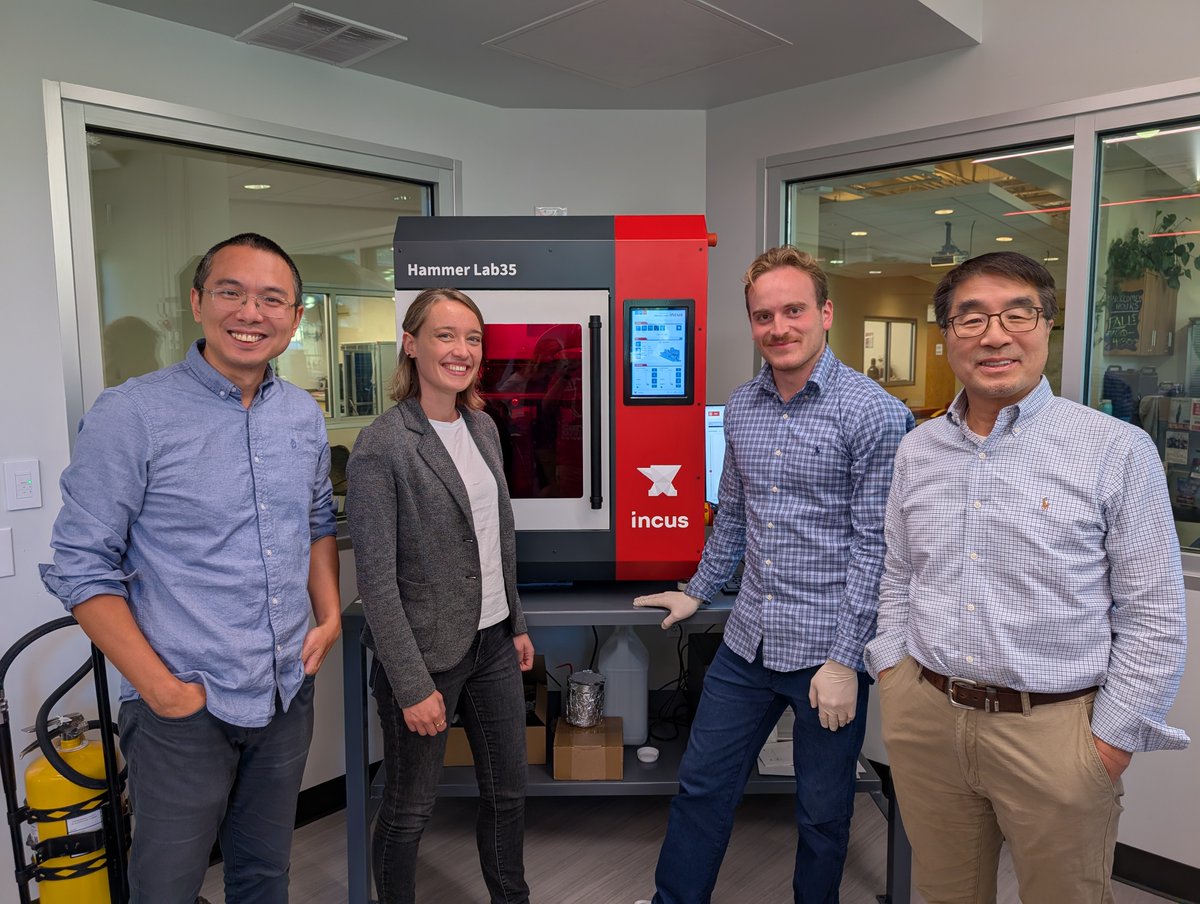

The University of Utah's Powder PM Lab has installed the Hammer Lab35 3D printer, marking a significant milestone in its pursuit of developing advanced materials. The 3D printer is set to enhance the lab's research, enabling further development of sinter-based AM processes.

Next up is Atlanta! Incus' Head of R&D Materials, Dr. György Harakály, will present the latest breakthroughs in Lithography-based Metal Manufacturing at the ICAM conference organized by @ASTMIntl. Mark your calendars and contact us for more details! lnkd.in/gmUCVdcH

Incus CEO Dr. Gerald Mitteramskogler will talk about LMM technology in the #biomedical field on 16.10. at World PM in Japan. Don't miss your chance to discover the latest innovations in sinter-based AM for high-precision parts - register here: lnkd.in/gvqQKeuH #3dprinting

We are thrilled to invite you to visit us at booth 76-77 during the EURO PM, organized by the @EuroPMAssoc, in Sweden! From 30.09. to 02.10. Dr. György Harakály and Dr. Santiago Cano Cano, will present the latest advances in LMM technology across three sessions.

The Incus team welcomes the visitors at the @ReAMShow in Dubai! Come and visit our booth E17 to find out more about Lithography-based Metal Manufacturing technology for your production! #incus3d #3dprinting #metal3dprinting @ashukla09

We congratulate our team for 2nd place at the Sinter-based AM Workshop Component Award organized by @FraunhoferIFAM! Printed with stainless steel 316L, the bracelet requires no assembly & combines the precision of traditional manufacturing with unmatched design freedom! #incus3d

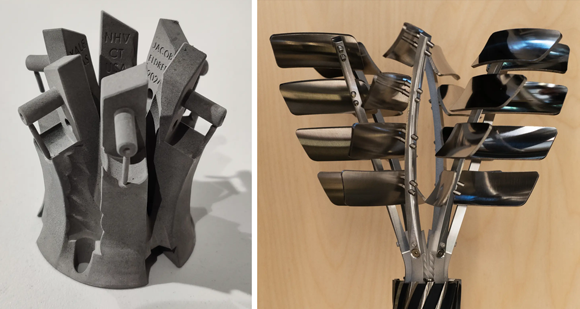

.@Incus3D has additively manufactured a #stainlesssteel 316L part for a ceremonial mace, designed by graduate Jacob Eldred, for @Yale’s School of Engineering - metal-am.com/incus-gmbhs-ad… #additivemanufacturing #3dprinting #university

We are looking forward to this year's PMTi2024 conference on 4-6.09, 2024, in Madrid! Our Senior Material Engineer Dr. Cano Cano will speak about the development of materials for LMM on the 2nd day of the conference. Secure your spot today by registering: lnkd.in/ghJEwTdg

Through a collaborative effort, Incus & Sarto Electro, one of India’s leading #jewelry machinery trading companies, have produced stunning rings featuring highly intricate & detailed designs. Each ring is crafted from 316L stainless steel & is presented as sintered. #india

Last week, Incus' Senior Material Developer Dr. Cano Cano gave a lecture at the WISE Summer School at @chalmersuniv. The students were introduced to the LMM technology and its endless possibilities with opportunities to discuss AM technologies, materials, and design aspects.

Day two in LA is off to a great start! We're thrilled to see a diverse range of visitors at our booth today and to showcase some exciting new applications. Stop by booth 1619 today and experience our Hammer Lab35 and #3dprinted parts firsthand! #3dprinting #incus3d #rapidtct

Excited to kick off the @RAPID_Event! Join us at the booth 1619 to see remarkable parts our partners MetShape, @MicroMIM_Europe and @IndoMim1 are creating with our innovative LMM technology! #incus3d #3dprinting #rapidtct

🚀 Counting down the hours to @RAPID_Event in LA! 🚀 Our dedicated team has worked tirelessly to showcase the Incus' #3DPrinting technology. Join us tomorrow at booth 1619 for an unforgettable experience as we unveil the latest innovations in LMM technology!

Today is the last day of the 3D Print Lyon exhibition! Our colleague @ModderDenise, Head of Application Engineering at Incus, will be happy to share insights into Lithography-based Metal Manufacturing and answer your question at booth A22!

United States Trends

- 1. Thanksgiving 387K posts

- 2. Golesh 2,356 posts

- 3. Fani Willis 14K posts

- 4. Trumplican 3,053 posts

- 5. #WipersDayGiveaway N/A

- 6. Hong Kong 82.2K posts

- 7. Khabib 7,386 posts

- 8. Camp Haven 7,057 posts

- 9. Tom Hardy 1,435 posts

- 10. NextNRG 1,044 posts

- 11. Stranger Things 163K posts

- 12. Riker N/A

- 13. Africans 27K posts

- 14. Ruth 14K posts

- 15. #TejRan 4,154 posts

- 16. Idris 7,707 posts

- 17. Elijah Moore 1,038 posts

- 18. Fassbender N/A

- 19. Karoline Leavitt 29.7K posts

- 20. Ribs 11.7K posts

Something went wrong.

Something went wrong.