Knops Ear

@KnopsEar

Knops, the volume button for your ears. Control your volume 🎛 Pre-order on Indiegogo. Contact us at [email protected] 💻📨

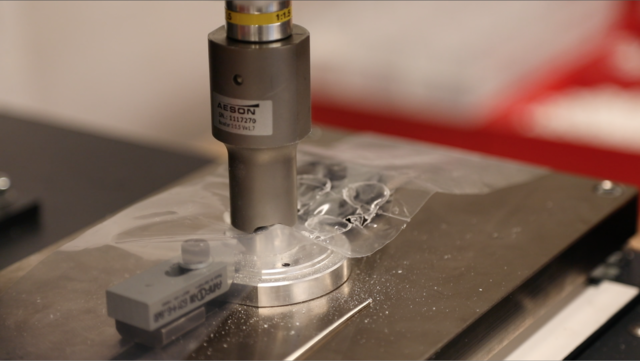

You might be wondering why we do this step of the production process by hand. As this is a very important, detailed step of the production process, fulfilling it by hand means we can ensure maximum quality control. ✨

It's kind of satisfying right, seeing us smoothen your Knops by hand 🙌?

We are starting on the finishing touche(s). With this special tool, we smoothen the end part of Knops that attach to your ear tips by hand. This results in your Knops becoming smoother and perfectly being aligned to the different ear tips.

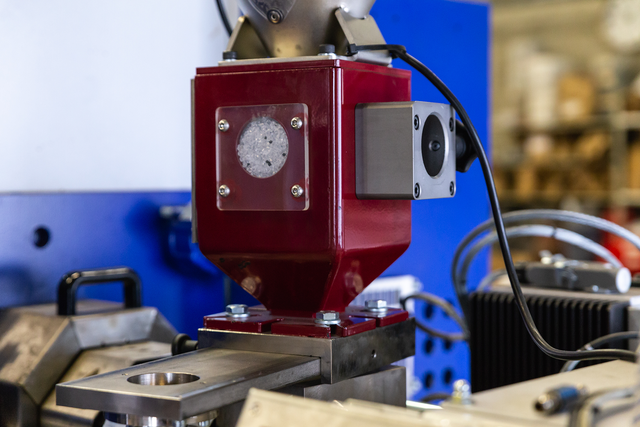

Boom: we have used our ultrasonic weld to press the different parts of Knops into each other. The foundation for your Knops is laid and we are now ready for the next step in our production process.

We have arrived at the third major step in the production of Knops. For this step, we use a press machine. We press the main parts of Knops into each other. The unique mechanism that enables you to switch between the four different Knops settings know works!

Our production is now as smooth as switching between the four filter settings of Knops. In order for Knops to run this smoothly, some parts need lubrication. This makes the parts fit together smoothly and operating Knops a breeze.🔩

Previously, we had to manually sort the parts and see if all parts were correct. We have streamlined this process to make it a lot easier and time efficient. So, not only can make Knops cheaper now, we can also produce more and in the highest quality you expect from Knops.😃

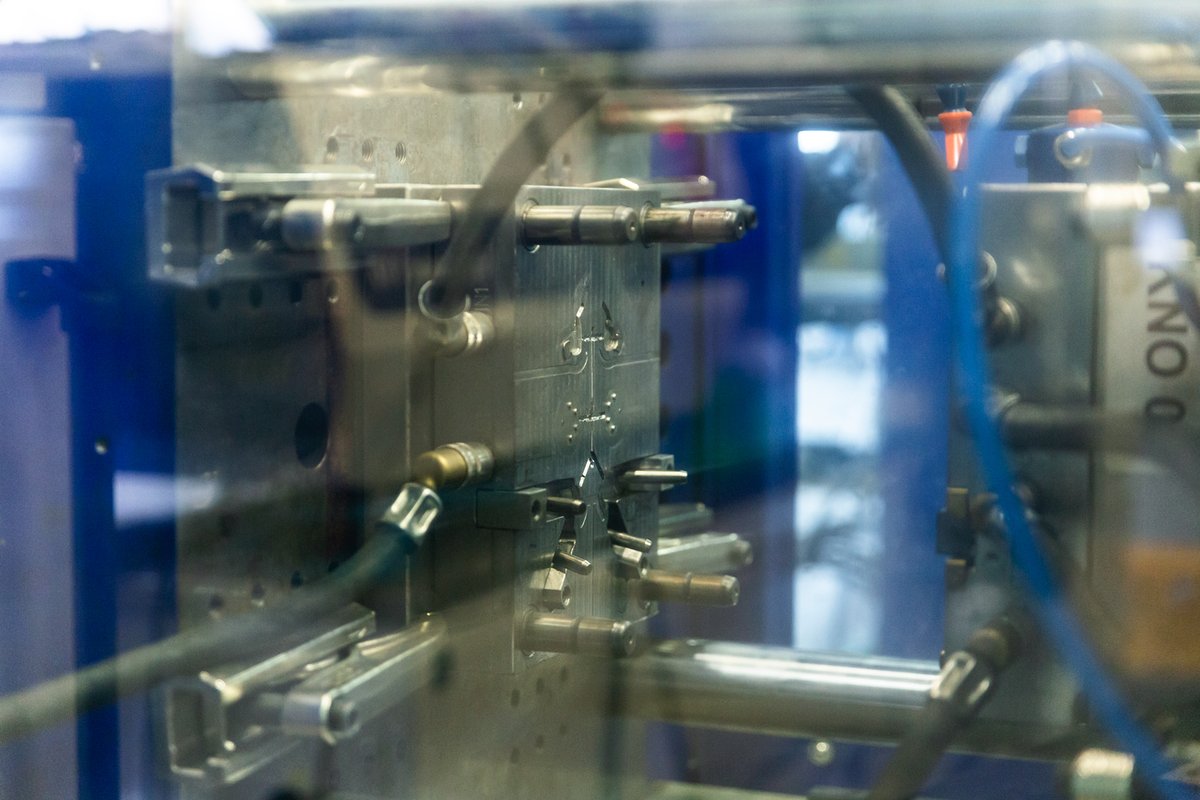

Wave goodbye to all those little particles behind the window. It's the last time you'll see them like this before they're made into the body of your Knops.👋

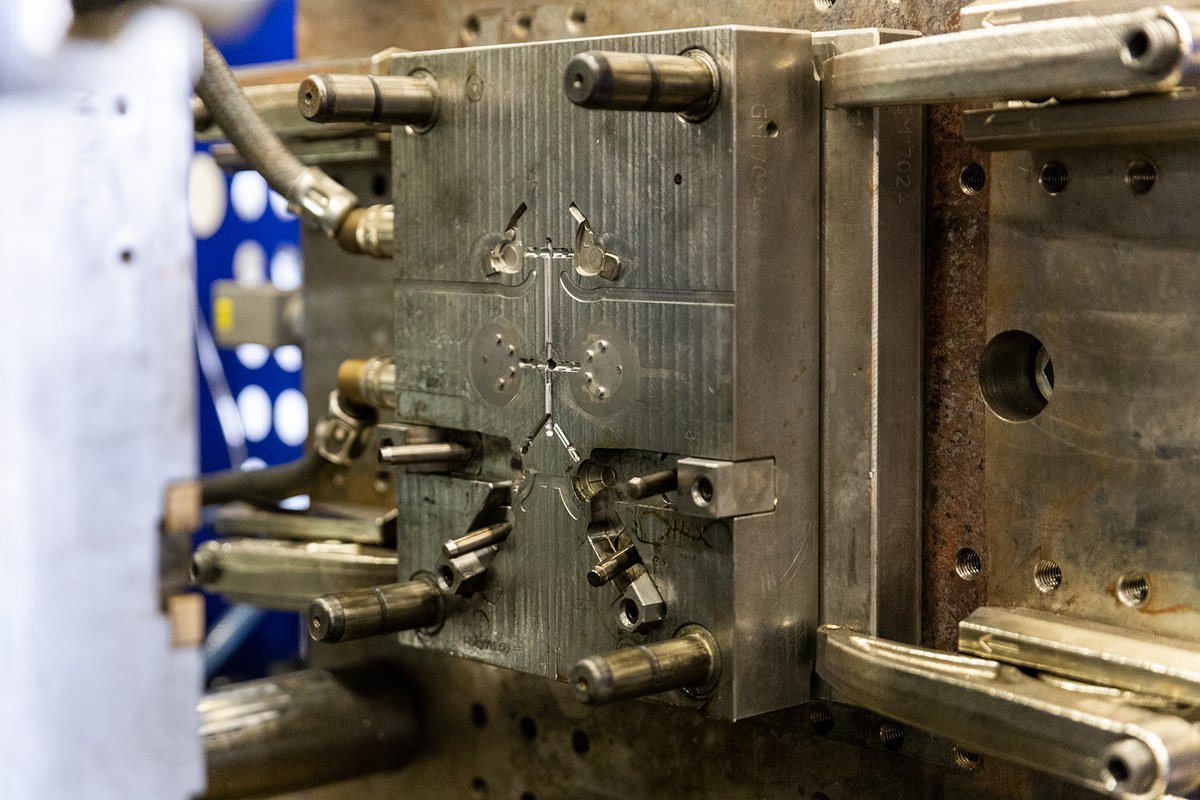

Getting the injection moulded parts together is a very sophisticated process. Can you imagine that more than twenty parts go trough this process and into your Knops?

Today, we focus on the moulds. It's important that these moulds perfectly align with the other parts so there's no leakage inside the final product. After numerous tests & checks, the moulds are finally optimised to perfection, streamlining the process and creating airtight Knops

Have you noticed any problems with your hearing due to you listening to (too) loud music? > knops.co/hearing-volume…

The smart hearing device that you need. @KnopsEar READ MORE:- techniblogic.com/control-hear-s…

Proud to be the 2,322nd 😎 on @BackerKit for Knops - The volume button for.... Thanks @KnopsEar knops-igg.backerkit.com/hosted_preorde…

knops-igg.backerkit.com

Pre-order Knops - The volume button for your ears on BackerKit

What if you could adjust the volume of life itself? Turn down or turn up. Anytime, anywhere.

Een volumeknop voor je oor, en nog hip ook trouw.nl/home/een-volum… via @trouw

trouw.nl

Een volumeknop voor je oor, en nog hip ook

Een volumeknop is niks bijzonders, we passen er dagelijks het geluidsniveau van de tv of smartphone mee aan. Maar nu is er ook een volumeknop voor je oor.

Proud to be the 2,292nd 😎 on @BackerKit for Knops - The volume button for.... Thanks @KnopsEar knops-igg.backerkit.com/hosted_preorde…

knops-igg.backerkit.com

Pre-order Knops - The volume button for your ears on BackerKit

What if you could adjust the volume of life itself? Turn down or turn up. Anytime, anywhere.

Proud to be the 2,285th 😎 on @BackerKit for Knops - The volume button for.... Thanks @KnopsEar knops-igg.backerkit.com/hosted_preorde…

knops-igg.backerkit.com

Pre-order Knops - The volume button for your ears on BackerKit

What if you could adjust the volume of life itself? Turn down or turn up. Anytime, anywhere.

Excited to be the 2,246th 😎 on @BackerKit for Knops - The volume button for.... Thanks @KnopsEar knops-igg.backerkit.com/hosted_preorde…

knops-igg.backerkit.com

Pre-order Knops - The volume button for your ears on BackerKit

What if you could adjust the volume of life itself? Turn down or turn up. Anytime, anywhere.

United States Trends

- 1. Kittle 11,8 B posts

- 2. Josh Allen 50,5 B posts

- 3. AJ Brown 3.833 posts

- 4. Bills 153 B posts

- 5. 49ers 43,2 B posts

- 6. Jags 32,9 B posts

- 7. Eagles 134 B posts

- 8. Niners 12,8 B posts

- 9. Trevor Lawrence 15,2 B posts

- 10. #GoldenGlobes 82,5 B posts

- 11. Quinyon Mitchell 2.837 posts

- 12. Jake Elliot 1.507 posts

- 13. Demarcus Robinson 2.359 posts

- 14. #FTTB 6.507 posts

- 15. Jacksonville 16,2 B posts

- 16. #SFvsPHI 2.108 posts

- 17. Jaguars 43,4 B posts

- 18. Sirianni 3.509 posts

- 19. Erin Andrews 1.763 posts

- 20. Jalen 21,7 B posts

Something went wrong.

Something went wrong.