OralPro Tech

@OralProTech

Shaping the future of dentistry with AI, CAD/CAM & biomaterials

Controlled build-up ensures precise contacts and margins - eliminating chairside corrections. Keep contacts and margins as designed. Follow us to learn more! #Prosthodontics #DentalLab #CADCAM #QualityControl #OralProTech

Small choices protect fidelity. Set thickness, segment order, and moisture control to keep line angles and texture as designed. Protect your design fidelity. Learn more on our page today. #VeneeringCeramics #DentalLab #CADCAM #Prosthodontics #OralProTech

Verification is only as strong as the protocol. Lock scan-to-CAD alignment Record both RMS & Max µm Keep one acceptance band (≤50 µm RMS, ≤80 µm Max) Consistency = reproducibility. #DentalMetrology #CADCAM #DentalLab #Prosthodontics #OralProTech

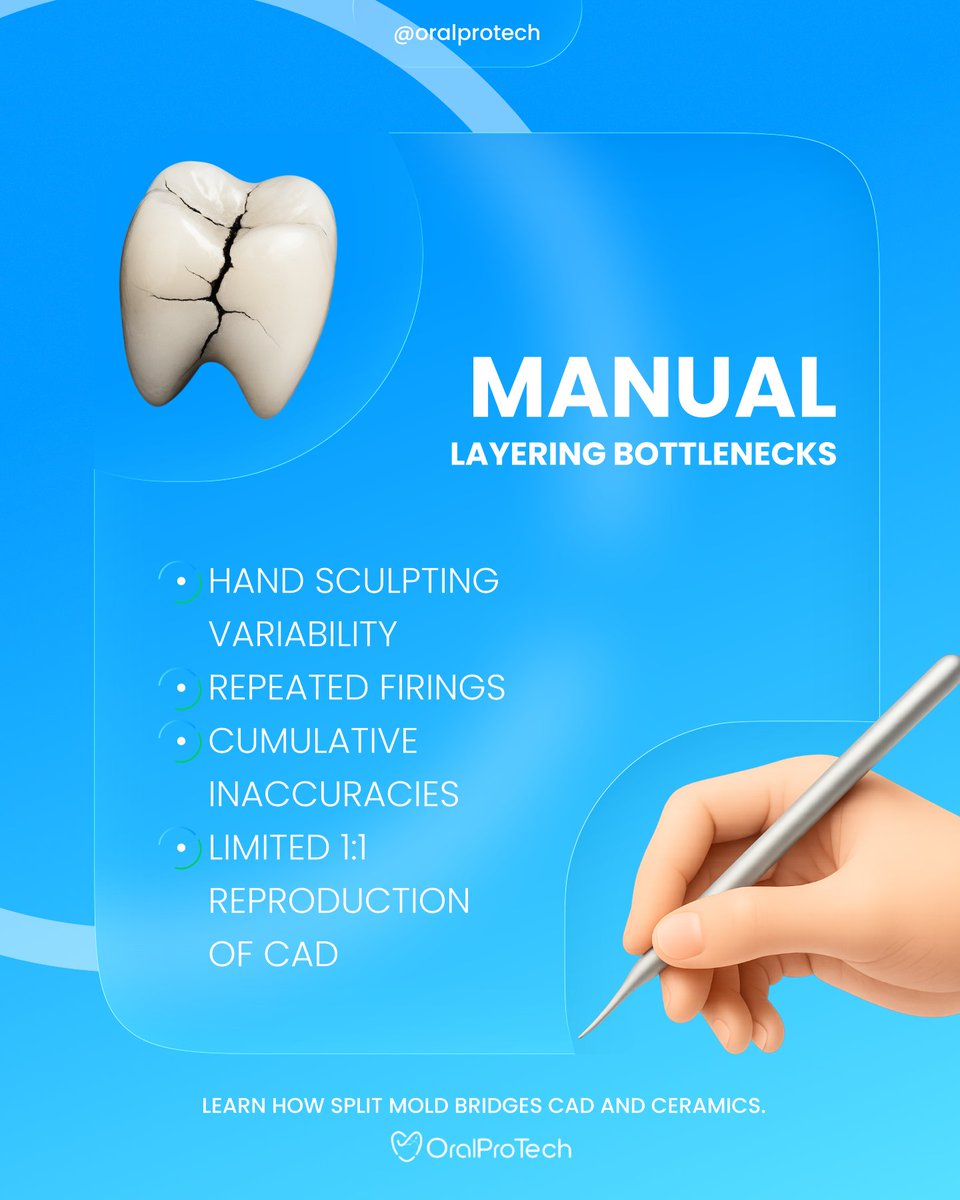

In traditional workflows, veneering ceramics are applied by hand — and even with experience, variability creeps in. Line angles shift. Texture softens. Margins move. Every case is unique — but not always reproducible. #DigitalDentistry #DentalLab #VeneeringCeramics #CADCAM

Our north star is simple: preserve the design you created and deliver it in ceramic with precision and reproducibility. Pilot opportunities will be open Q4 2025. This includes metal-ceramic restorations manufactured to match CAD full-contour designs. Join pilot or request a demo

A concise SOP helps labs adopt Split Mold consistently. Here’s the step-by-step overview for your workflow. #DentalSOP #LabStandards #CADCAM #Prosthodontics #DentalLab #OralProTech

Monolithic remains ideal for many cases. When the case requires veneering and 1:1 design fidelity, Split Mold provides the missing link. Discover how digital equals physical - without compromise. #Prosthodontics #DentalLab #VeneeringCeramics #OralProTech

Monolithic restorations are fast and strong, layered win on esthetics but risk CAD drift. Split Mold ensures ≤50 µm accuracy with controlled veneering for zirconia, lithium disilicate & metal-ceramics. #DigitalDentistry #CADCAM #OralProTech

Reducing variability supports efficiency. The objective is fewer adjustments and more predictable quality checks while you keep full control of outcomes. Discover how digital equals physical - without compromise. #DentalWorkflow #LeanLab #Prosthodontics #CADCAM #DentalTech

Esthetics rely on geometry. When line angles, texture, and emergence profile remain as designed, the visual intent translates. Learn how Split Mold bridges CAD and ceramics. #EstheticDentistry #Prosthodontics #CADCAM #DentalLab #VeneeringCeramics #OralProTech

Full contour is efficient. But when a case needs veneering ceramics, manual build-up can drift from CAD. Split Mold is the missing link. What it changes: design fidelity (line angles, texture, emergence profile, contacts, margins), reproducibility within a <50 µm target.

Repeatability matters. We evaluate RMS deviation against the original CAD to confirm geometry stays within the target tolerance band. See why ≤50 µm accuracy matters for restorations. Measurement note: example values from internal testing under controlled conditions.

You keep the tools you trust. Split Mold adds the missing piece at the veneering stage so the final geometry aligns with the CAD design — including veneering over metal substructures for metal-ceramic restorations. Discover how digital equals physical - without compromise.

Sub-50 µm tolerances support reproducibility. When geometry is preserved, try-ins are smoother and aesthetic intent remains intact. See why up to ≤50 µm accuracy matters for restorations. Measurement note: tolerances refer to internal test workflows under controlled protocols.

Split Mold enables a controlled build-up environment that reproduces the CAD design during veneering. The method is engineered to reduce variability and protect the original intent. Learn how Split Mold bridges CAD and ceramics #DentalInnovation #VeneeringCeramics #CADtoCeramic

Deviations from the CAD design often appear after layering and firing. We focus on preserving line angles, emergence profile, and texture as designed. See why up to <50 µm accuracy matters for restorations.

Labs know the pain points: each manual step can compound shape drift. Our goal is simple - preserve the CAD design through the veneering stage with precision. Learn how Split Mold bridges CAD and ceramics. #DentalLab #CeramicLayering #Prosthodontics #DentalWorkflow

Full contour restorations are efficient, but when a case requires veneering ceramics the only path is manual layering. That introduces operator variability and cumulative inaccuracies that move the result away from the digital intent. Discover how digital equals physical.

United States Trends

- 1. #UFC322 38.2K posts

- 2. Ewing 5,623 posts

- 3. Bama 19.2K posts

- 4. Wellmaker 3,986 posts

- 5. Oklahoma 29.2K posts

- 6. Noah Thomas N/A

- 7. #AEWCollision 4,578 posts

- 8. Wingo 1,294 posts

- 9. Ty Simpson 3,850 posts

- 10. Arch 17.6K posts

- 11. Jeremiah Smith 2,065 posts

- 12. Bronny 5,038 posts

- 13. Boomer Sooner 2,173 posts

- 14. #GoDawgs 5,133 posts

- 15. Georgia 78.8K posts

- 16. Iowa 20.1K posts

- 17. UConn 4,721 posts

- 18. Sabatini 1,385 posts

- 19. Lagway 1,264 posts

- 20. Shapen N/A

Something went wrong.

Something went wrong.