Slice Engineering

@SliceEngineer

Industrial 3D Printer Components, Designed To Be Forgotten. Stay zesty.

You might like

Take your Prusa MINI to the next level 🚀 Our plug-and-play hotend solution eliminates heat creep, prevents clogs & boosts performance, powered by our Copperhead® Hot Block + Bimetallic Heat Break™. 👉 sliceengineering.com/products/prusa… #3DPrinting

Thinking of upgrading your printer to the Mosquito Hotend? Here are some of the benefits you'll gain: ⚫ Effortless One-Handed Nozzle Changes™ ⚫ Access to engineering-grade plastics ⚫ Bimetallic Heat Break™ to eliminate heat creep Shop now: sliceengineering.com/products/the-m…

Got a Mako® Hotend on your setup? We want to see it in action!🦈🦈🦈 Show off your latest prints or let us know what you’re creating with your MAKO! 📸 Share your build and tag us! #3DPrinting #SliceEngineering

On this Veterans Day, we want to express our deepest gratitude to those who have served our country. Thank you for your service! #VeteransDay #SliceEngineering

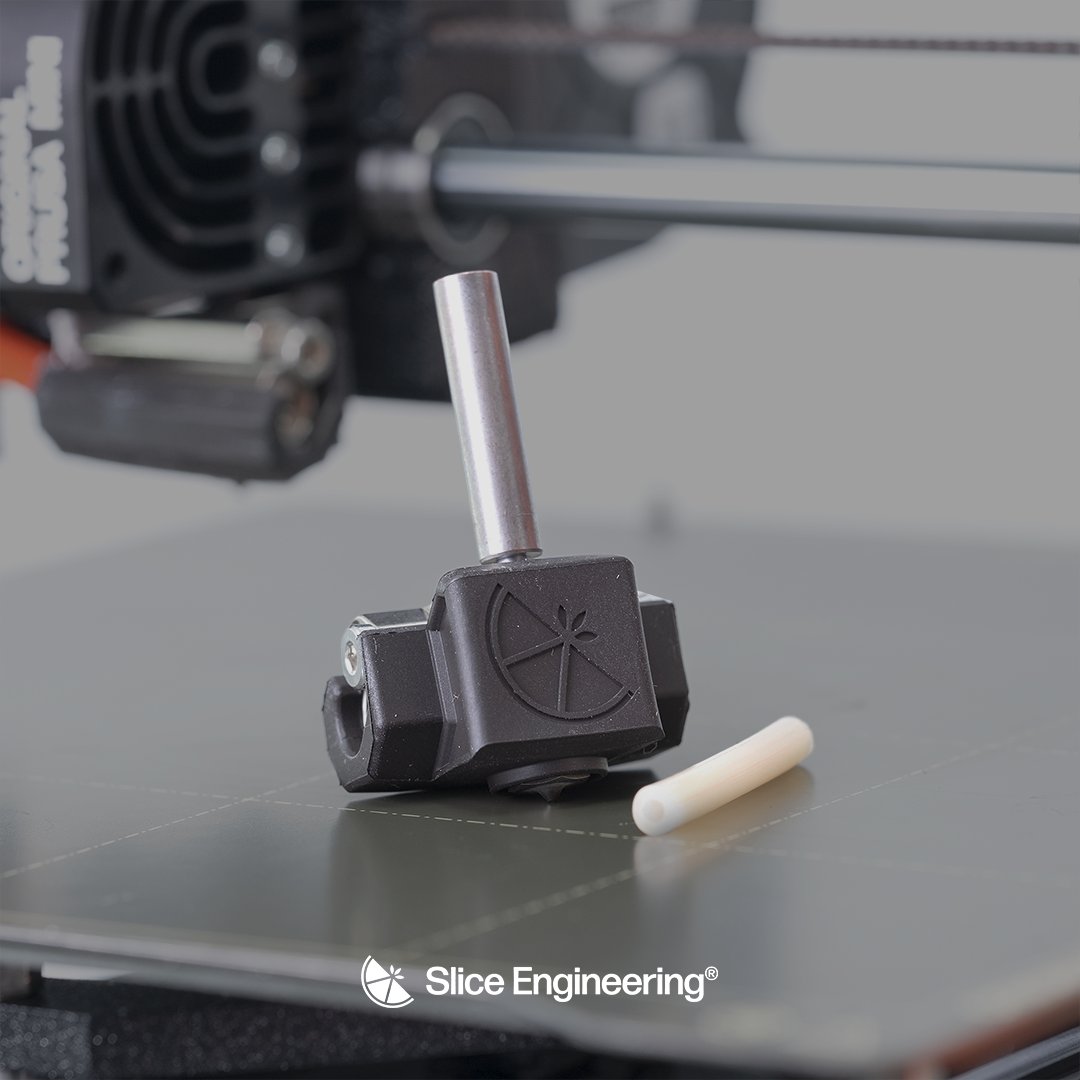

Ever wonder how the Mosquito® Hotend got its name? 🦟 Besides being developed in Gainesville, Florida (where mosquitoes are everywhere), the standoff tubes reminded us of a mosquito’s legs. Shop now 👉 sliceengineering.com/products/the-m… #3DPrinting #SliceEngineering

Plastic Repellent Paint™ keeps your 3D printer nozzle clean by repelling plastic and preventing buildups, giving you smoother, more precise prints with less maintenance and more uptime. Shop now 👉 sliceengineering.com/products/plast… #3DPrinting #SliceEngineering

Looking to improve the heat transfer on your printer? Try one of our thermal compounds. ❝A massive upgrade to the standard thermal paste that comes on 3d printers. Isn't hard to work with and heat transfer is perfect.❞ - Gregory P. Shop now 👉 sliceengineering.com/collections/th…

🔧 Push the limits of your 3D printer with the Mosquito Magnum+®! Engineered for high-flow, high-temperature printing, our Magnum+ delivers exceptional speeds and flawless results for professional and industrial-grade applications. 👉 Shop now: sliceengineering.com/products/mosqu…

🌍 Additive manufacturing is leveling the playing field for small businesses globally. It enables innovators to produce complex parts cost-effectively, customize designs freely, and manufacture on demand without huge investments. How has 3D printing changed the game for you?

Tired of plastic building up on your nozzle and causing print failures? 👉 Shop our solution here: sliceengineering.com/products/plast… #SliceEngineering #3DPrinting

The GammaMaster® Nozzle is the next evolution in nozzle technology, designed for abrasive filament printing that doesn't sacrifice thermal conductivity. 👉 Shop now: sliceengineering.com/products/gamma… #SliceEngineering #3DPrinting

With exceptional thermal efficiency, clog-free printing, and effortless One-Handed Nozzle Changes™, the Mosquito® Hotend is the upgrade your printer has been waiting for. Check it out here: sliceengineering.com/products/the-m… #3DPrinting #MosquitoHotend #SliceEngineering

Moisture ruins prints. 💧 Keep your filament dry with Slice Engineering® Desiccant for flawless results.

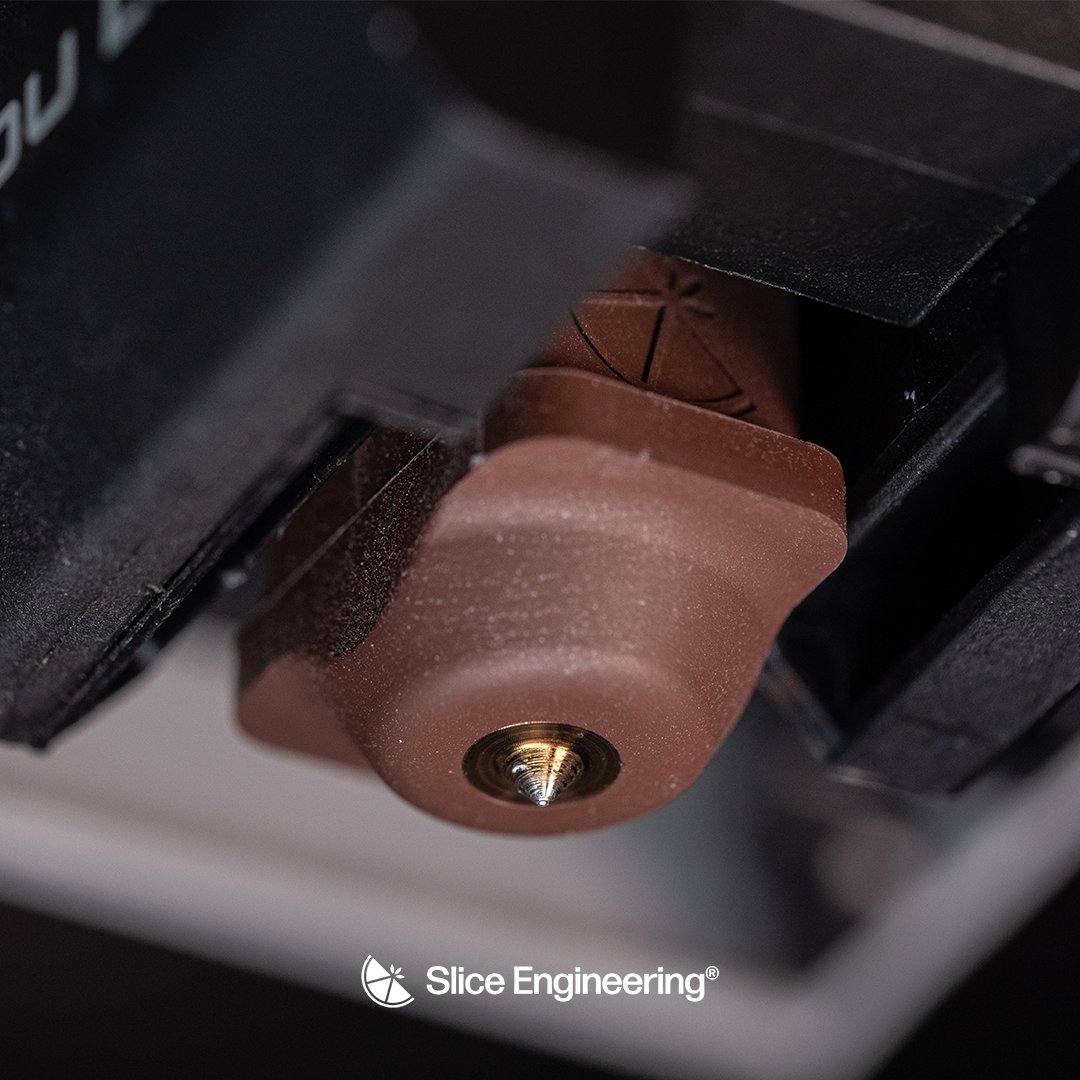

Silicone Boots add thermal insulation, guard against heat loss, and shield your hot block and nozzle from unwanted airflow and filament. For reliable performance, choose boots that are tear-resistant & easy to install. 👉Check ours out here: sliceengineering.com/collections/si… #3DPrinting

Why does additive manufacturing matter? It's a catalyst for innovation, enabling rapid prototyping and mass customization. This tech is revolutionizing how we create, from aerospace to medical devices. ✨ Read more: sliceengineering.com/blogs/news/why… #3Dprinting #SliceEngineering

Additive manufacturing is a game-changer for military supply chains, enabling on-the-spot repairs and innovation. At Slice, we're honored to support our military customers and those who serve. It's a privilege to play a part in their mission. #3Dprinting #SliceEngineering

Unleash the full potential of your Bambu Lab printer with the Mako® Hotend 🦈🦈🦈! With quick-change nozzles and 65% faster print speeds, you'll be able to tackle projects faster than ever. Shop now: sliceengineering.com/products/mako-… #3Dprinting #SliceEngineering

Liquid-Cooled Hotends Unlike air-cooled systems, liquid-cooled hotends use circulating coolant to move heat away from the hotend. This enables stable performance inside heated chambers, even under extreme printing conditions. #3DPrinting #SliceEngineering

Our 2.4 mm GammaMaster® Nozzle really does exist 😱 Designed for printing prosthetics & large-format applications, it lays down serious filament with ease. 👉To learn more, click here: sliceengineering.com/products/gamma… #SliceEngineering

🚀 Did you know that NASA is experimenting with boron nitride, the same component used in our Boron Nitride Paste, for test enclosures on Mars? Here's why it stands out: ▪️Extremely high thermal stability & conductivity ▪️Non-electrically conductive sliceengineering.com/products/boron…

United States Trends

- 1. Ravens 54.7K posts

- 2. Ravens 54.7K posts

- 3. Lamar 43.6K posts

- 4. Joe Burrow 18.7K posts

- 5. Zay Flowers 3,921 posts

- 6. #WhoDey 3,397 posts

- 7. Cowboys 89.6K posts

- 8. Derrick Henry 4,308 posts

- 9. Zac Taylor 2,568 posts

- 10. #heatedrivalry 6,390 posts

- 11. #CINvsBAL 2,597 posts

- 12. Perine 1,526 posts

- 13. Harbaugh 2,879 posts

- 14. AFC North 2,183 posts

- 15. Mahomes 33K posts

- 16. Sarah Beckstrom 198K posts

- 17. Cam Boozer 2,086 posts

- 18. Jason Garrett N/A

- 19. Tanner Hudson 1,250 posts

- 20. Myles Murphy N/A

You might like

-

Bondtech

Bondtech

@BondtechAB -

3D Printing Nerd™

3D Printing Nerd™

@3dprintingnerd -

Marlin Firmware

Marlin Firmware

@MarlinFirmware -

Stefan - CNC Kitchen

Stefan - CNC Kitchen

@CNC_Kitchen -

Thomas Sanladerer

Thomas Sanladerer

@madewithlayers -

Prusament

Prusament

@prusament -

Chris Riley

Chris Riley

@chrisriley3d -

3D Maker Noob 🇲🇹

3D Maker Noob 🇲🇹

@3DMakerNoob -

BIGTREETECH

BIGTREETECH

@BigTreeTech -

Phaetus3D

Phaetus3D

@phaetus3D -

E3D

E3D

@E3DOnline -

Protopasta

Protopasta

@Proto_pasta -

Nero3D the Canuck Creator

Nero3D the Canuck Creator

@CanuckCreator -

3DChameleon

3DChameleon

@3DChameleon -

3D Gloop!

3D Gloop!

@3DGloop

Something went wrong.

Something went wrong.