Collider

@collidertech

Our machine makes parts faster, cheaper, and in materials 3D printing has never been able to access. We #3dprint production ready parts in ideal geometries.

“This unique combination of attributes—modern infrastructure, economic incentives and good old Southern hospitality—explains yet another aspect of #Chattanooga’s juxtaposition: the combination of small #startup businesses and decades’ old multinationals.”

What's #manufacturing look like in the southern US? Here's a tour of the industrial goings-on of #Chattanooga, TN -> ow.ly/gmpt30lwO9Z

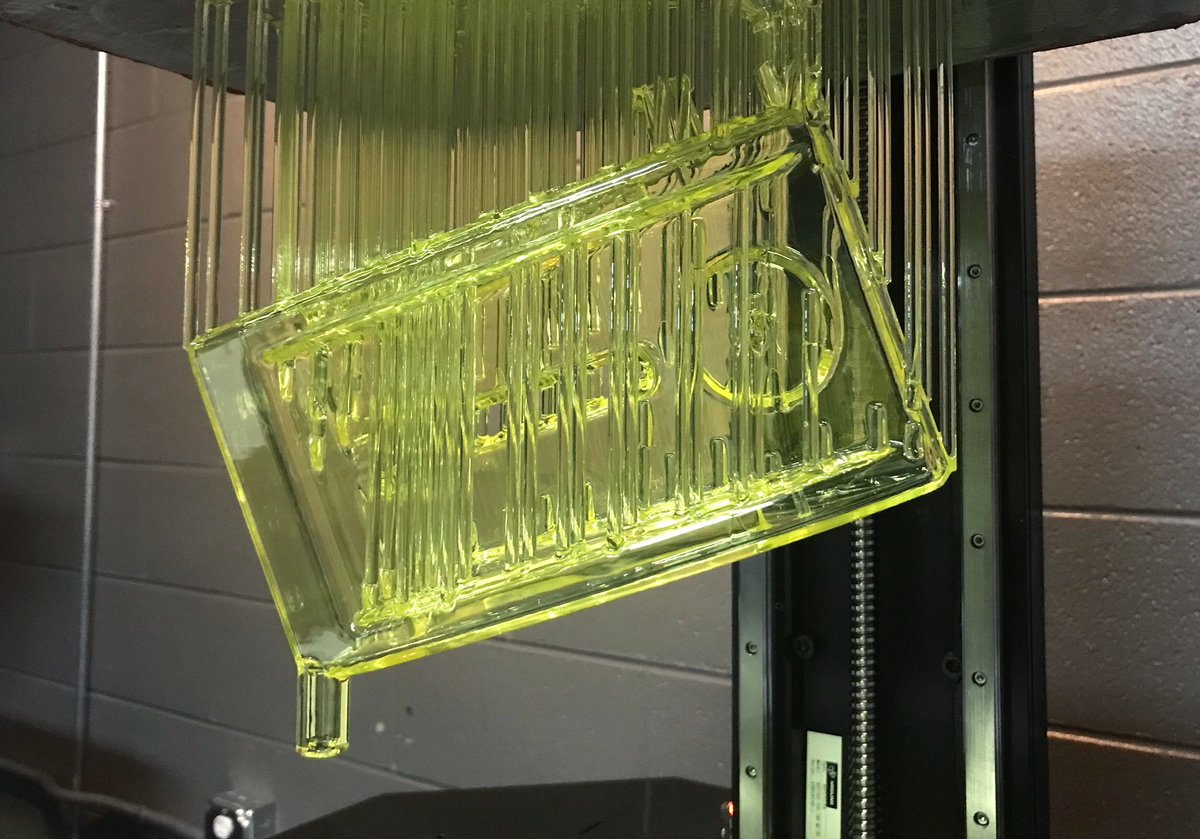

Check out this bracket Haley Piske—our mechanical engineer—designed and #3Dprinted for our next generation #3Dprinter. It holds a resin reservoir so you can work without worrying your prints will run out of resin. #tech #manufacturing

Are you ready for the weekend? We are! Featuring: Joseph Alnas and Zach Kies #team #FridayFunDay

Check out this shoe #insole! @wiivvit designed it and we #3Dprinted it with our #programmabletooling #tech. Material: Smooth Cast 322 by @SmoothOn Dye: SO-Strong by @SmoothOn #AdditiveManufacturing #3Dprinting

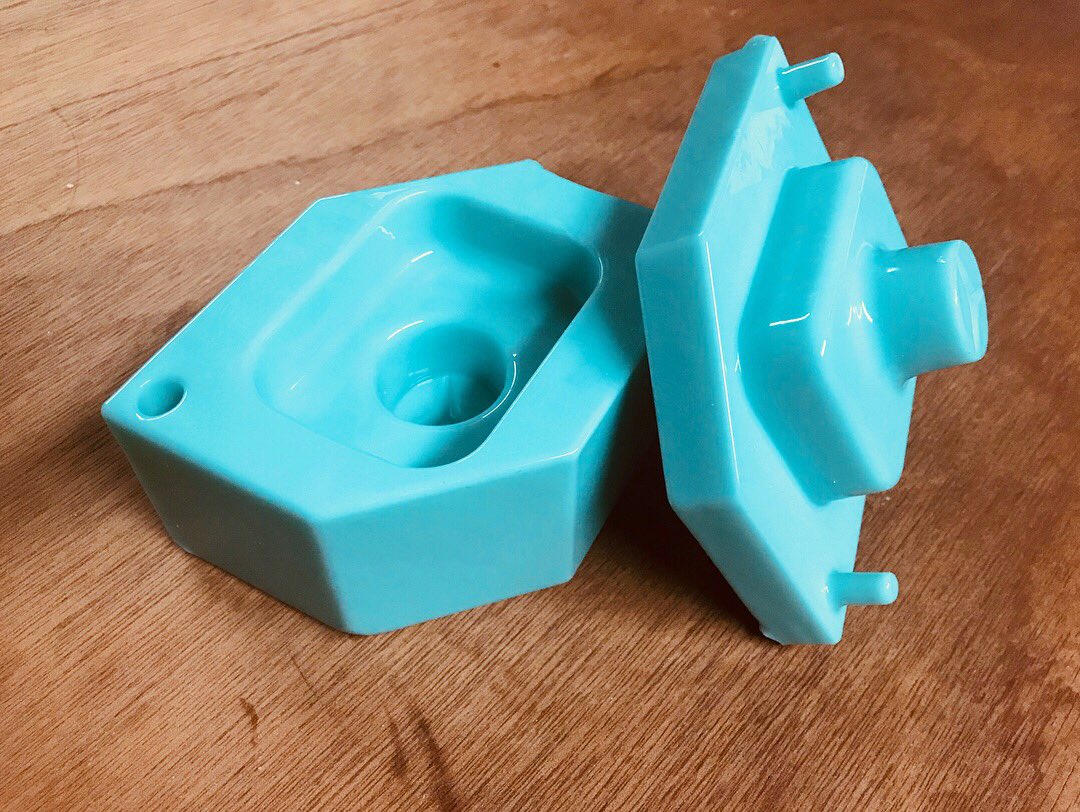

Check out this funnel #mold we #3Dprinted in silicone. Our #programmabletooling #tech created this silicone mold at a much lower cost than traditional #manufacturing. Mold design by @TRINOTA_3D (trinota.com) Material: Mold Max 40 by @SmoothOn

Congratulations to all the finalist in the Rise of the Rest pitch competition. Good Luck to @AegleGear , @BranchTechno , and @cprwrap ! colab.co/2018/04/rise-o… #Chattanooga #RiseofRest #Incubators #accelerators #startups

@injii @Passitdown @BranchTechno @collidertech @RapidRMS @FreightWaves @truckingtalk @AmbitionSales @BoudinetJ @audiencepoint @BellhopsMoving @camdoody @skuidify @owtdoorguy Congrats on being featured in our 10 Best Tech Startups in Chattanooga! thetechtribune.com/10-best-tech-s…

United States الاتجاهات

- 1. Peggy 31.8K posts

- 2. Sonic 06 2,276 posts

- 3. Berseria 4,638 posts

- 4. Zeraora 13.8K posts

- 5. Cory Mills 28.2K posts

- 6. #ComunaONada 3,267 posts

- 7. $NVDA 46.1K posts

- 8. Randy Jones N/A

- 9. Dearborn 372K posts

- 10. Ryan Wedding 3,732 posts

- 11. Luxray 2,327 posts

- 12. Encyclopedia Galactica 5,450 posts

- 13. #CurrysPurpleFriday 12.7K posts

- 14. Saudi Investment Forum 2,967 posts

- 15. International Men's Day 81.9K posts

- 16. Cooks 10.1K posts

- 17. Xillia 2 N/A

- 18. #wednesdaymotivation 8,073 posts

- 19. #Wednesdayvibe 2,940 posts

- 20. Rick Hendrick 1,026 posts

Something went wrong.

Something went wrong.