#cracktesting 搜尋結果

🔍 New Flex Probes for Crack Testing! Get precise results even on curved surfaces with our adaptable Flex Probes. Perfect for testing various part geometries—no scanning equipment needed. Reproducible, reliable results. Contact us to learn more! #CrackTesting #QualityAssurance

Acquire knowledge on the detection of cracks and hardness defects in rotor shafts utilizing FOERSTER's STATOVISION. hubs.la/Q01XpFmM0 #CrackTesting #MicrostructureTesting

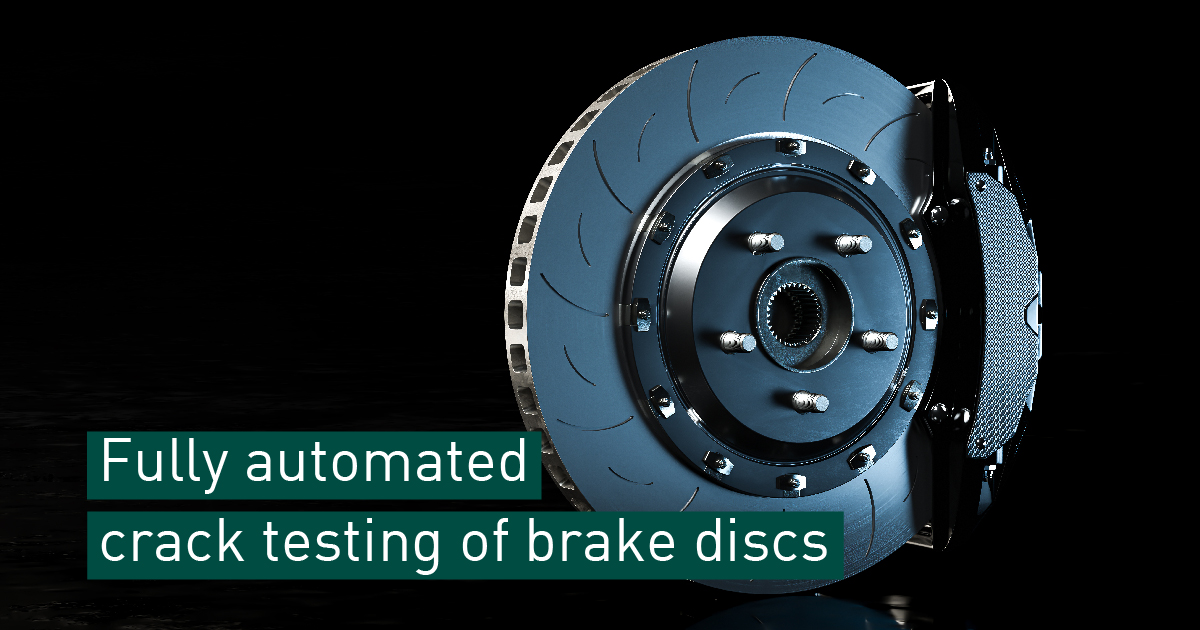

Find out how to test brake discs for cracks. How does crack detection work? What are the solutions available? Click now to learn more! Find out more: hubs.la/Q01BDzny0 #FullyAutomatedCrackTesting #BrakeDiscInspection #CrackTesting

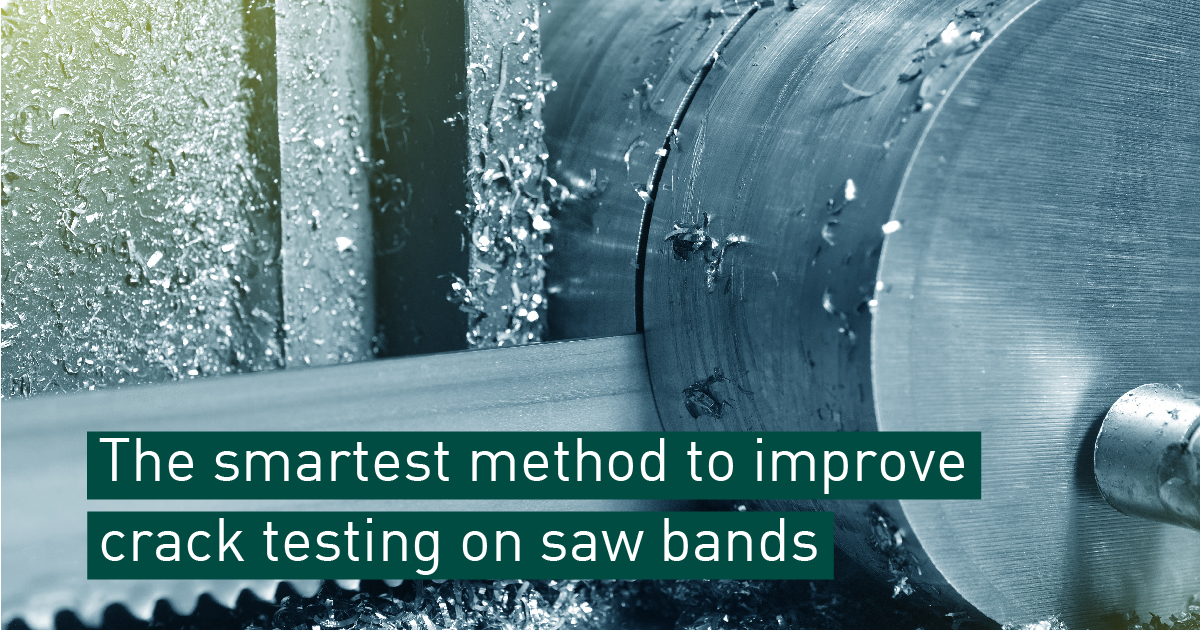

Learn about FOERSTER's solution for testing saw bands. An eddy current testing device capable of detecting and documenting surface defects. Click here: hubs.la/Q01BDH_H0 #CrackTesting #SmartCrackDetection #InnovativeTestingMethods

Get an insight into a wide variety of methods used for crack detection, including magnetic particle inspection, dye penetrant inspection, ultrasound, and more. Find out more: hubs.la/Q01BDv5l0 #MaterialsTesting #QualityControl #CrackTesting

What are the most common mistakes in crack testing, and how can you prevent them? Get to know FOERSTER's solution for powerful demagnetization. Read more: hubs.la/Q01BFF9Q0 #CrackTestingMistakes #CrackTesting #TestingSolutions

For successful crack testing with eddy current, correctly adjusted filter settings are indispensable. Get to know FOERSTER's solution for automatic parameter optimization. Click here: hubs.la/Q01BFR6D0 #NDTMethods #CrackTesting #QualityControlTesting

Crack testing is crucial for safety-critical components. Learn about the 6 key methods and common mistakes to avoid in non-destructive testing. #NDT #CrackTesting #FOERSTER #SafetyFirst Click here: hubs.la/Q02FxWCs0

blog.foerstergroup.com

The most common mistakes in crack testing - and their solution!

What are the most common mistakes in crack testing and how can you prevent them? Get to know FOERSTER's solution for powerful demagnetization.

When it comes to #CrackTesting, eddy current is one of the most effective methods for testing metal (near-)surfaces for #defects. hubs.la/Q01n9cBv0 #FOERSTER #NDT #inspection #QualityAssurance #signal hubs.la/Q01n92PN0

blog.foerstergroup.com

Crack testing: How does an eddy current test instrument work?

Get to know the eddy current method of the crack testing instrument. Check out FOERSTER's solution STATOGRAPH CM+ / CM.

How to determine the optimal settings of filters and frequencies during #CrackTesting with #EddyCurrent? Find that out in our #NewBlogPost. #NDT #MakingQualityVisible hubs.ly/H0VS70M0

#EddyCurrent testing is one of the most effective methods for testing (near-)surfaces for defects. Want to know what are the important influencing factors for #CrackTesting and how to choose optimal settings? Find that our in today's #blog post. hubs.la/Q0107d9b0

blog.foerstergroup.com

Crack testing: How does an eddy current test instrument work?

Get to know the eddy current method of the crack testing instrument. Check out FOERSTER's solution STATOGRAPH CM+ / CM.

To help you match high standards, particularly when it comes to the inspection of brake discs, we have developed the #STATOVISION software. Want to find out more? hubs.la/H0wr30k0 #ndt #CrackTesting #ComponentTesting #FOERSTER

Turn unplanned downtime into a thing of the past. Regular planned Integrity Inspection is a great defense against equipment failure. #Inspection #foodsafety #cracktesting #INDEi #contamination indei.global lnkd.in/gVsmaff

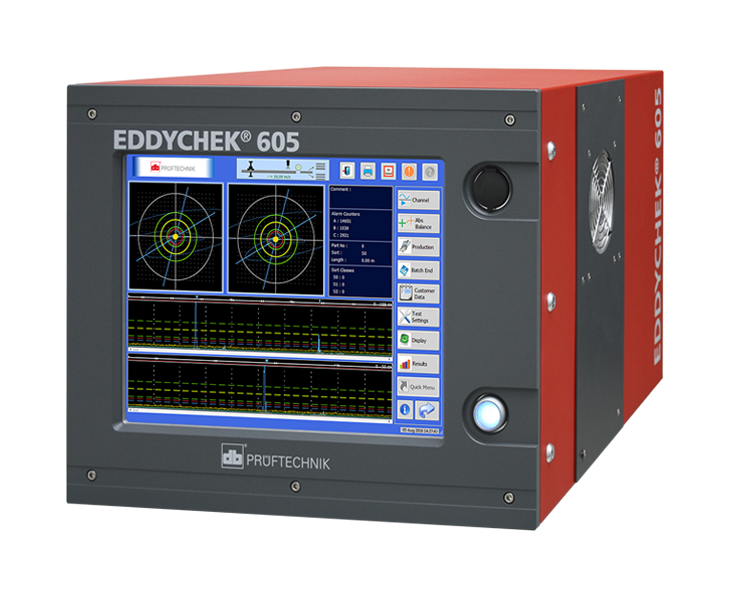

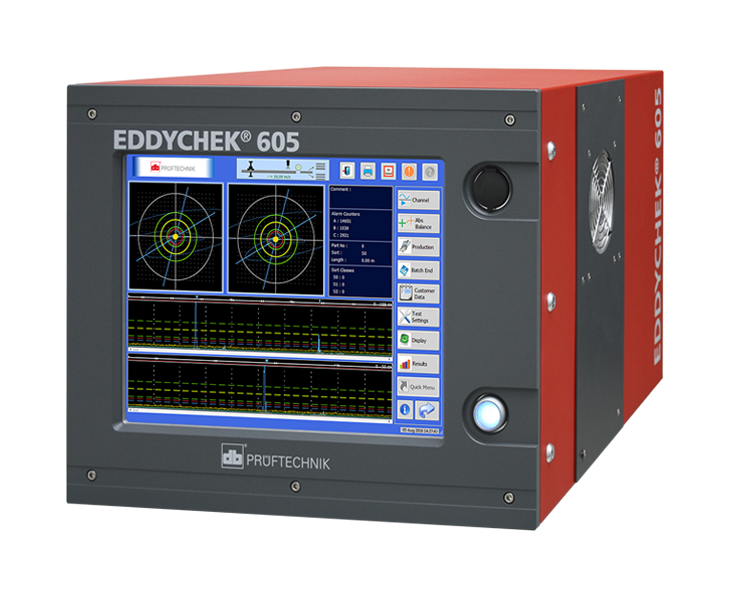

#NondestructiveTesting of semi-finished metal parts directly in your drawing line with #EDDYCHECK 605. Classic #cracktesting with encircling coil, fast rotating system and automatic distance compensation, #weldingSeam check and more. Find out more >pruftechnik.com/com/Products-a…

Following the recent news and scares about spray dyers, we have produced a case study about the various NDT methods and applications regarding inspection, advantages and disadvantages. #spraydryer #cracktesting #testing #maintenance lnkd.in/eg528fY

Crack testing is crucial for safety-critical components. Learn about the 6 key methods and common mistakes to avoid in non-destructive testing. #NDT #CrackTesting #FOERSTER #SafetyFirst Click here: hubs.la/Q02FxWCs0

blog.foerstergroup.com

The most common mistakes in crack testing - and their solution!

What are the most common mistakes in crack testing and how can you prevent them? Get to know FOERSTER's solution for powerful demagnetization.

🔍 New Flex Probes for Crack Testing! Get precise results even on curved surfaces with our adaptable Flex Probes. Perfect for testing various part geometries—no scanning equipment needed. Reproducible, reliable results. Contact us to learn more! #CrackTesting #QualityAssurance

Acquire knowledge on the detection of cracks and hardness defects in rotor shafts utilizing FOERSTER's STATOVISION. hubs.la/Q01XpFmM0 #CrackTesting #MicrostructureTesting

For successful crack testing with eddy current, correctly adjusted filter settings are indispensable. Get to know FOERSTER's solution for automatic parameter optimization. Click here: hubs.la/Q01BFR6D0 #NDTMethods #CrackTesting #QualityControlTesting

What are the most common mistakes in crack testing, and how can you prevent them? Get to know FOERSTER's solution for powerful demagnetization. Read more: hubs.la/Q01BFF9Q0 #CrackTestingMistakes #CrackTesting #TestingSolutions

Learn about FOERSTER's solution for testing saw bands. An eddy current testing device capable of detecting and documenting surface defects. Click here: hubs.la/Q01BDH_H0 #CrackTesting #SmartCrackDetection #InnovativeTestingMethods

Find out how to test brake discs for cracks. How does crack detection work? What are the solutions available? Click now to learn more! Find out more: hubs.la/Q01BDzny0 #FullyAutomatedCrackTesting #BrakeDiscInspection #CrackTesting

Get an insight into a wide variety of methods used for crack detection, including magnetic particle inspection, dye penetrant inspection, ultrasound, and more. Find out more: hubs.la/Q01BDv5l0 #MaterialsTesting #QualityControl #CrackTesting

When it comes to #CrackTesting, eddy current is one of the most effective methods for testing metal (near-)surfaces for #defects. hubs.la/Q01n9cBv0 #FOERSTER #NDT #inspection #QualityAssurance #signal hubs.la/Q01n92PN0

blog.foerstergroup.com

Crack testing: How does an eddy current test instrument work?

Get to know the eddy current method of the crack testing instrument. Check out FOERSTER's solution STATOGRAPH CM+ / CM.

#EddyCurrent testing is one of the most effective methods for testing (near-)surfaces for defects. Want to know what are the important influencing factors for #CrackTesting and how to choose optimal settings? Find that our in today's #blog post. hubs.la/Q0107d9b0

blog.foerstergroup.com

Crack testing: How does an eddy current test instrument work?

Get to know the eddy current method of the crack testing instrument. Check out FOERSTER's solution STATOGRAPH CM+ / CM.

How to determine the optimal settings of filters and frequencies during #CrackTesting with #EddyCurrent? Find that out in our #NewBlogPost. #NDT #MakingQualityVisible hubs.ly/H0VS70M0

New website launch for the food and beverage industries. indei.global #inspection #ndt #cracktesting

🔍 New Flex Probes for Crack Testing! Get precise results even on curved surfaces with our adaptable Flex Probes. Perfect for testing various part geometries—no scanning equipment needed. Reproducible, reliable results. Contact us to learn more! #CrackTesting #QualityAssurance

#NondestructiveTesting of semi-finished metal parts directly in your drawing line with #EDDYCHECK 605. Classic #cracktesting with encircling coil, fast rotating system and automatic distance compensation, #weldingSeam check and more. Find out more >pruftechnik.com/com/Products-a…

Want to make sure your valve housings and valve sleeves are delivered intact and undamaged? Learn more: hubs.ly/H0rPR0D0 #ndt #CrackTesting #Technology #CrackInspection #MP

Find out how to test brake discs for cracks. How does crack detection work? What are the solutions available? Click now to learn more! Find out more: hubs.la/Q01BDzny0 #FullyAutomatedCrackTesting #BrakeDiscInspection #CrackTesting

Learn about FOERSTER's solution for testing saw bands. An eddy current testing device capable of detecting and documenting surface defects. Click here: hubs.la/Q01BDH_H0 #CrackTesting #SmartCrackDetection #InnovativeTestingMethods

Get an insight into a wide variety of methods used for crack detection, including magnetic particle inspection, dye penetrant inspection, ultrasound, and more. Find out more: hubs.la/Q01BDv5l0 #MaterialsTesting #QualityControl #CrackTesting

What are the most common mistakes in crack testing, and how can you prevent them? Get to know FOERSTER's solution for powerful demagnetization. Read more: hubs.la/Q01BFF9Q0 #CrackTestingMistakes #CrackTesting #TestingSolutions

For successful crack testing with eddy current, correctly adjusted filter settings are indispensable. Get to know FOERSTER's solution for automatic parameter optimization. Click here: hubs.la/Q01BFR6D0 #NDTMethods #CrackTesting #QualityControlTesting

Acquire knowledge on the detection of cracks and hardness defects in rotor shafts utilizing FOERSTER's STATOVISION. hubs.la/Q01XpFmM0 #CrackTesting #MicrostructureTesting

Something went wrong.

Something went wrong.

United States Trends

- 1. #WorldSeries 65.2K posts

- 2. #SmackDown 13.2K posts

- 3. Snell 6,175 posts

- 4. Halo 133K posts

- 5. Darryn Peterson 1,309 posts

- 6. PlayStation 62.8K posts

- 7. Purdue 5,946 posts

- 8. Celtics 16.8K posts

- 9. $BIEBER N/A

- 10. Knicks 20.3K posts

- 11. #LetsGoDodgers 5,573 posts

- 12. Xbox 76.2K posts

- 13. Zion 13.6K posts

- 14. Cole Anthony N/A

- 15. End of 1 13.9K posts

- 16. Tyler Kolek 1,298 posts

- 17. Yesavage 6,416 posts

- 18. Jasper Johnson N/A

- 19. End 1Q N/A

- 20. End of the 1st 2,810 posts