#lindeengineering search results

In 1902, Carl von Linde created the world’s first air separation unit #ASU for oxygen production, revolutionizing the industry. Over 100 years later, we're still at the forefront. Read more: fal.cn/3vUVi #LindeEngineering

This impressive view is of our Liquefied Natural Gas (LNG) plant in Bintulu, Malaysia. As we keep moving towards a greener energy economy, LNG will become a more vital clean energy source #LindeEngineering #FutureTechnology #CleanEnergy #LiquidNaturalGas

Hydrogen is rarely produced at the point of use. So how can the point of production be connected to the point of use? Learn more about the vision for a hydrogen future: fal.cn/3pMOb #LindeEngineering #Sustainability #GasProcessing

About 35 percent of industrial CO2 #emissions come from burning fossil fuels to generate high-temperature heat. #LindeEngineering constructs and retrofits plants with equipment and infrastructure for carbon capture. fal.cn/3vX7c

Unidades HyCO (Syngas) construídas de acordo com os requisitos para hidrogénio e monóxido de carbono #UnidadesHyCO #LindeEngineering #Hidrogénio #Monóxidodecarbono

#News A 35-megawatt PEM (Proton Exchange Membrane) electrolyzer to produce green #hydrogen in Niagara Falls, New York, will be built by Linde Engineering. The new plant will be the largest electrolyzer installed by Linde globally. #LindeEngineering fal.cn/3rI4v

On the way to a carbon-free future, leveraging existing natural gas pipelines and blending hydrogen gas with natural gas can be an option to meet the growing need for a high-volume pipeline distribution infrastructure. Learn more fal.cn/3qKHR #LindeEngineering

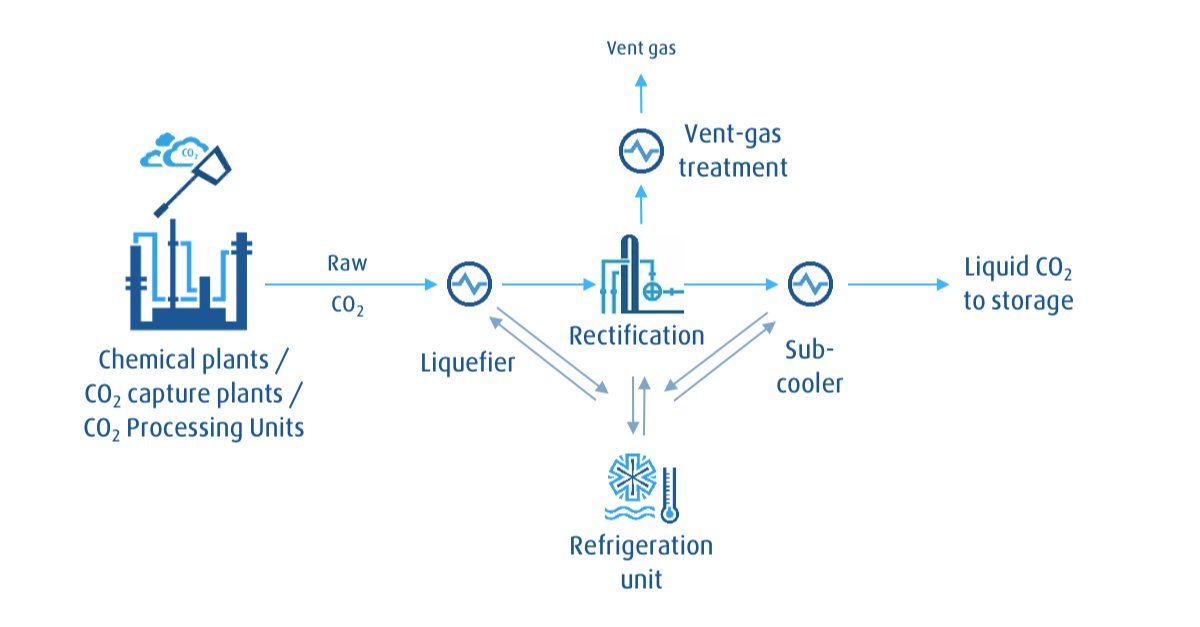

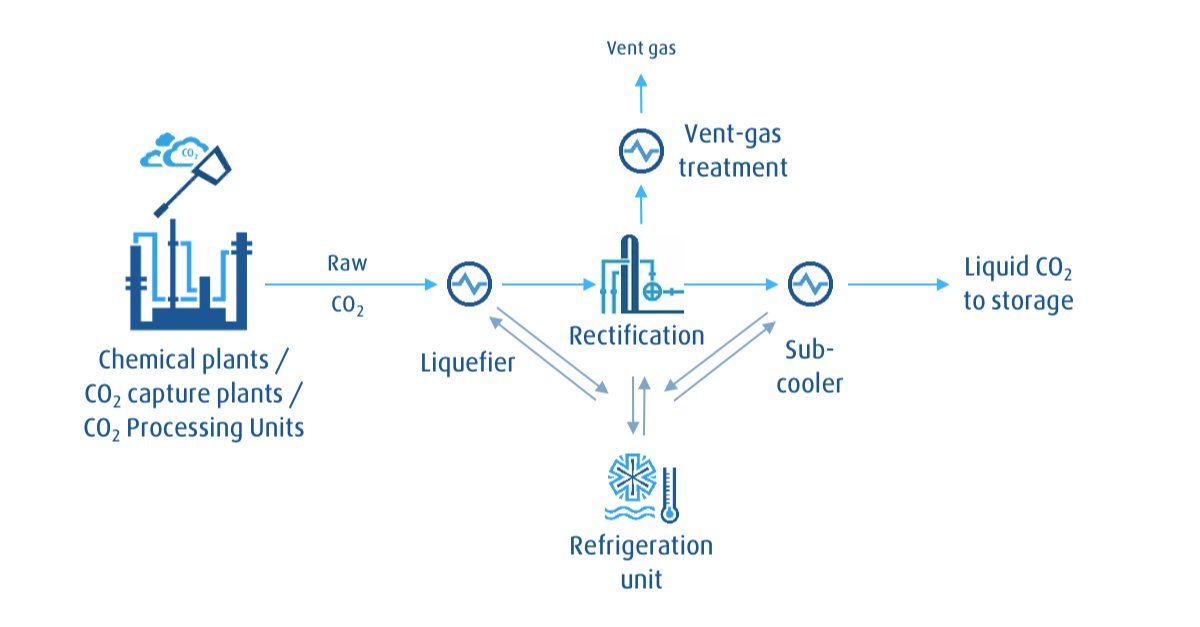

After capturing CO2, #liquefaction is a typical building block for the downstream CO2 conditioning. At Linde’s largest liquefaction plant approximately 1,350 tons of CO2 per day are produced. Learn more about the CO2 liquefaction process: fal.cn/3sj7J #LindeEngineering

#News Linde successfully started up its fifth air separation unit in Yantai, China, for the Wanhua Chemical Group. All five ASUs, built and operated by Linde, have the capacity to operate flexibly, resulting in higher reliability. #LindeEngineering fal.cn/3sDj2

Output and productivity of air separation units (#ASU) have increased tremendously. An eight-train ASU built in 2010 produces 860.000 cubic meters of oxygen per hour. Carl von Linde’s first one in 1902 managed three cubic meters. #LindeEngineering fal.cn/3t92i

#LindeEngineering offers an outstanding thermal HydroDeAlkylation (HDA) process to produce benzene from refinery and petrochemical streams. The benefits include low hydrogen consumption and best-in-class energy. Learn more: fal.cn/3qGzf #efficiency.

Daimler Truck ve Linde, hidrojen yakıt dolumunda yeni bir dönem başlatıyor #daimlertruck #lindeengineering insaatteknik.com/sirket-haberle…

Linde Engineering to supply ASU and nitrogen wash unit to Australia’s largest urea plant Read More: ow.ly/JNbx50QNxWn #LindeEngineering #ASU #ureaplant #nitrogenwashunit #Australia

#News Linde will build a second Air Separation Unit (ASU) at the Kalinganagar Industrial Estate in Odisha, East India, to supply industrial gases to Jindal Stainless Limited (JSL), one of the largest stainless-steel producers in India. #LindeEngineering fal.cn/3sVIN

Linde has a long history in the production and supply of acetylene gas, mainly for welding applications and as a chemical intermediate. Today we gladly share our know-how with our customers. Find out how: fal.cn/3q2jQ #LindeEngineering #GasProcessing

Did you know that it’s possible to capitalize on power and price fluctuations? With its FLEXASU® project, #LindeEngineering is helping to balance grid fluctuations as the renewable share increases. Learn more: fal.cn/3qRp5 #Innovation #FLEXASU #Sustainability

Latest Addition! Brand New High Reach Combi for the New Branch in Huddersfield. We also have 4 New Linde FLT's also arriving this week! #lindeengineering #combilift #investment

Linde’s PyroCrack® technology handles the full spectrum of feedstocks. Its twin cell design allows independent cracking of different feedstocks in one furnace. Learn more about how #LindeEngineering can drive your cracker plant to higher #Efficiency. fal.cn/3tJ6a

Linde has 60 years of experience with #acetylene recovery. Benefits of our processes and technology: ✔ extremely pure ethylene streams ✔ no fouling or corrosion problems ✔ flexibility for all plant operating cases #LindeEngineering #ProcessingPlants fal.cn/3vus8

With state-of-the-art digitalization and automation technologies for steam crackers, #LindeEngineering is adapting to the increasing demand for ethylene. Examples are the use of digital twins and automatic mode change. Learn more: fal.cn/3tsHu #SteamCracking

Linde to deliver cryogenic plant for world’s first utility-scale quantum computer in Australia indianchemicalnews.com/technology/lin… #LindeEngineering #PsiQuantum #cryogenic #quantumcomputer @LindEngineering @PsiQuantum

indianchemicalnews.com

Linde to deliver cryogenic plant for world’s first utility-scale quantum computer in Australia

The cryogenic cooling technology will enable PsiQuantum's first utility-scale quantum computer

Expansions: @Borouge to expand olefin/polyolefins capacity in Ruwais; Vioneo awards FEED to Wood for Belgian biopolymer project; plasticsandrubberasia.com/may2025/materi… #LindeEngineering #Vioneo #Wood #APMollerGroup

Briefs: BASF Performance Material and Linde Engineering indianchemicalnews.com/general/briefs… #BASFPerformanceMaterial #LindeEngineering @BASF @LindeIndia1

indianchemicalnews.com

Briefs: BASF Performance Material and Linde Engineering

BASF and Wall Technology are expanding strategic partnership to drive sustainable innovation in polyisocyanurate (PIR) sandwich panels for cold chain applications

Linde Engineering has entered into an agreement with NEXTCHEM to deliver advanced carbon capture technology for the Abu Dhabi National Oil Company’s (ADNOC) Hail &Ghasha project. tinyurl.com/4x8uf2h2 @NextChem_MT @ADNOCGroup #LindeEngineering #GasProduction #OilProduction

Linde to supply new carbon capture technology to ADNOC’S Hail and Ghasha project indianchemicalnews.com/technology/lin… #LindeEngineering #Linde #Maire #Nextchem #ADNOC #gas @LindEngineering @Lindeplc @MaireGroup @NextChem_MT @ADNOCGroup

Linde Engineering to Build 100 MW Green Hydrogen Plant for Shell’s REFHYNE II #Hydrogen #ITMPower #LindeEngineering #REFHTNEII #Technology #solarnews #solar #power #greenenergy #renewableenergy urjadaily.com/linde-engineer…

Daimler Truck ve Linde, hidrojen yakıt dolumunda yeni bir dönem başlatıyor #daimlertruck #lindeengineering insaatteknik.com/sirket-haberle…

Daimler Truck ve Linde'den Yeni Hidrojen Dolum Teknolojisi ‘sLH2’ kasadergisi.com/daimler-truck-… #DaimlerTruck #LindeEngineering #Mercedes #MercedesBenzTürk

Daimler Truck ve Linde'den Yeni Hidrojen Dolum Teknolojisi ‘sLH2’ kargohaber.com/daimler-truck-… #DaimlerTruck #LindeEngineering #Mercedes #MercedesBenzTürk

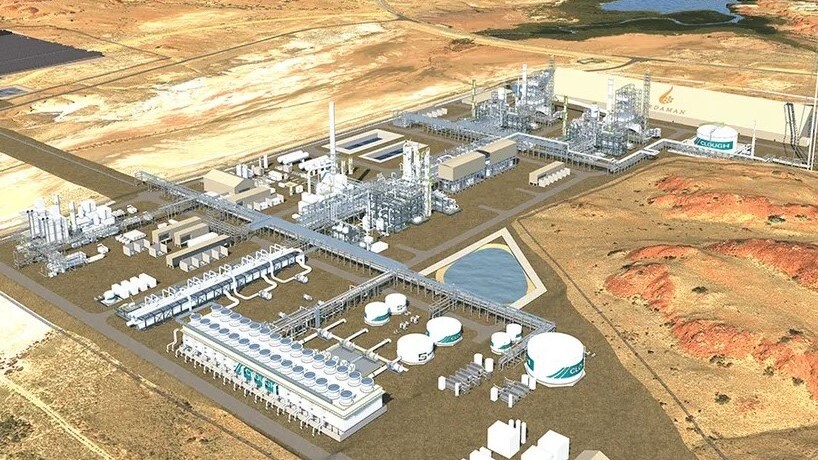

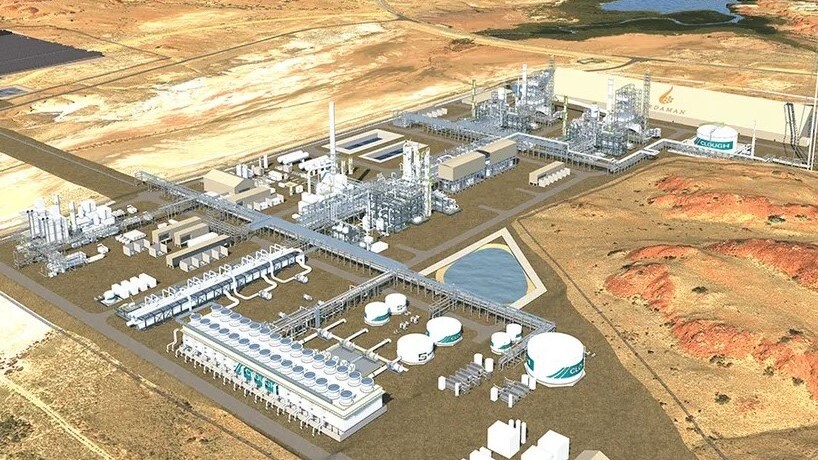

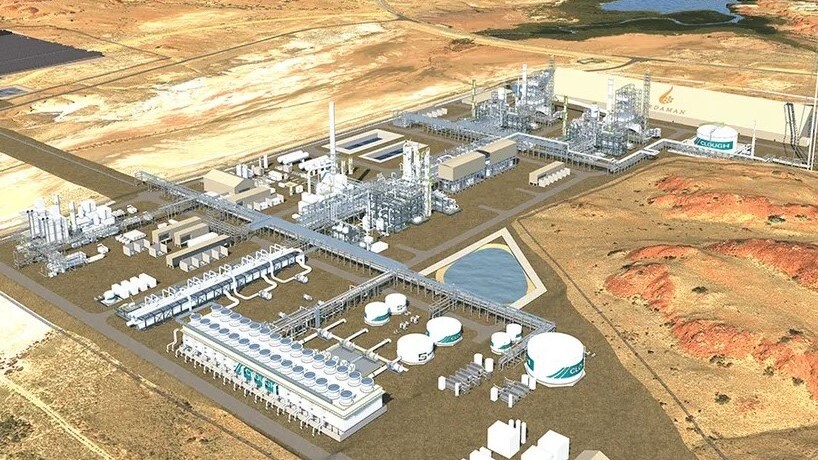

Linde Engineering to supply ASU and NWU to Perdaman's urea plant in Australia indianchemicalnews.com/technology/lin… #LindeEngineering #Linde #PerdamanIndustries #ureaplant @LindEngineering @Lindeplc

Linde Engineering to supply ASU and nitrogen wash unit to Australia’s largest urea plant Read More: ow.ly/JNbx50QNxWn #LindeEngineering #ASU #ureaplant #nitrogenwashunit #Australia

Linde Engineering to deliver CO2 liquefaction plant to Yara indianchemicalnews.com/technology/lin… #LindeEngineering #Yara #JuergenNowicki #MichaelSchlaug #Sluiskilproject @LindEngineering @yara

indianchemicalnews.com

Linde Engineering to deliver CO2 liquefaction plant to Yara

After start-up in 2026, it will be a part of one of the first commercial carbon-capture-storage (CCS) ventures in Europe

Linde Engineering to deliver world-scale coastal CO2 Liquefaction Plant to Yara Read More: ow.ly/WXhb50QJre8 #LindeEngineering #CO2LiquefactionPlant #Yara #Netherlands

In the @LindEngineering Case Study that was featured in the @FT, there was a remarkable 72.4% reduction in workplace incidents through the impact of coaching. performanceconsultants.com/safety-culture… #SafetyCulture #CoachingSuccess #LindeEngineering #WorkplaceSafety

Linde set new standard for liquid hydrogen refueling technology indianchemicalnews.com/hydrogen/linde… #DaimlerTruck #LindeEngineering #AndreasGorbach #JuergenNowicki @DaimlerTruck @LindEngineering

indianchemicalnews.com

Linde set new standard for liquid hydrogen refueling technology

Today, liquid hydrogen can be supplied reliably throughout Europe

In a significant development in the chemical industry, @SABIC has teamed up with #SD, a world leader in Ethylene Glycol Technology, and Linde Engineering. tinyurl.com/2p8dcndh @LindEngineering #LindeEngineering #chemicalindustry #ethyleneglycol

MF Hydra mit dem gut sichtbaren weißen Wasserstofftank. Der Dampf ist Wasserdampf.©Norled Oslo, 31. März 2023. Die norwegische Reederei Norled hat am 31. März die weltweit erste Wasserstoff-Fähre in Betrieb genommen. #LindeEngineering #MHHydra #Norled businessportal-norwegen.com/2023/04/03/wel…

#LindeEngineering puts petrochemicals on a CO₂ diet. At the top of the list is the Steam Cracker - embedded in a holistic solution on the way to net-zero. Find out how we’re working on this goal: fal.cn/3wYr9

In 1902, Carl von Linde created the world’s first air separation unit #ASU for oxygen production, revolutionizing the industry. Over 100 years later, we're still at the forefront. Read more: fal.cn/3vUVi #LindeEngineering

Daimler Truck ve Linde, hidrojen yakıt dolumunda yeni bir dönem başlatıyor #daimlertruck #lindeengineering insaatteknik.com/sirket-haberle…

Linde Engineering to supply ASU and nitrogen wash unit to Australia’s largest urea plant Read More: ow.ly/JNbx50QNxWn #LindeEngineering #ASU #ureaplant #nitrogenwashunit #Australia

Unidades HyCO (Syngas) construídas de acordo com os requisitos para hidrogénio e monóxido de carbono #UnidadesHyCO #LindeEngineering #Hidrogénio #Monóxidodecarbono

MF Hydra mit dem gut sichtbaren weißen Wasserstofftank. Der Dampf ist Wasserdampf.©Norled Oslo, 31. März 2023. Die norwegische Reederei Norled hat am 31. März die weltweit erste Wasserstoff-Fähre in Betrieb genommen. #LindeEngineering #MHHydra #Norled businessportal-norwegen.com/2023/04/03/wel…

Hydrogen is rarely produced at the point of use. So how can the point of production be connected to the point of use? Learn more about the vision for a hydrogen future: fal.cn/3pMOb #LindeEngineering #Sustainability #GasProcessing

Daimler Truck ve Linde'den Yeni Hidrojen Dolum Teknolojisi ‘sLH2’ kasadergisi.com/daimler-truck-… #DaimlerTruck #LindeEngineering #Mercedes #MercedesBenzTürk

Linde Engineering to deliver world-scale coastal CO2 Liquefaction Plant to Yara Read More: ow.ly/WXhb50QJre8 #LindeEngineering #CO2LiquefactionPlant #Yara #Netherlands

About 35 percent of industrial CO2 #emissions come from burning fossil fuels to generate high-temperature heat. #LindeEngineering constructs and retrofits plants with equipment and infrastructure for carbon capture. fal.cn/3vX7c

After capturing CO2, #liquefaction is a typical building block for the downstream CO2 conditioning. At Linde’s largest liquefaction plant approximately 1,350 tons of CO2 per day are produced. Learn more about the CO2 liquefaction process: fal.cn/3sj7J #LindeEngineering

#News Linde successfully started up its fifth air separation unit in Yantai, China, for the Wanhua Chemical Group. All five ASUs, built and operated by Linde, have the capacity to operate flexibly, resulting in higher reliability. #LindeEngineering fal.cn/3sDj2

#LindeEngineering offers an outstanding thermal HydroDeAlkylation (HDA) process to produce benzene from refinery and petrochemical streams. The benefits include low hydrogen consumption and best-in-class energy. Learn more: fal.cn/3qGzf #efficiency.

Output and productivity of air separation units (#ASU) have increased tremendously. An eight-train ASU built in 2010 produces 860.000 cubic meters of oxygen per hour. Carl von Linde’s first one in 1902 managed three cubic meters. #LindeEngineering fal.cn/3t92i

#News A 35-megawatt PEM (Proton Exchange Membrane) electrolyzer to produce green #hydrogen in Niagara Falls, New York, will be built by Linde Engineering. The new plant will be the largest electrolyzer installed by Linde globally. #LindeEngineering fal.cn/3rI4v

Hydrogen (H2) is becoming a central talking point as the world moves towards a net-zero energy economy. Learn more about how hydrogen can help meet the goals outlined in the Paris Climate Agreement. fal.cn/3p4mT #LindeEngineering #CarbonFootprint #GasProcessing

#News Linde will build a second Air Separation Unit (ASU) at the Kalinganagar Industrial Estate in Odisha, East India, to supply industrial gases to Jindal Stainless Limited (JSL), one of the largest stainless-steel producers in India. #LindeEngineering fal.cn/3sVIN

Linde has a long history in the production and supply of acetylene gas, mainly for welding applications and as a chemical intermediate. Today we gladly share our know-how with our customers. Find out how: fal.cn/3q2jQ #LindeEngineering #GasProcessing

Latest Addition! Brand New High Reach Combi for the New Branch in Huddersfield. We also have 4 New Linde FLT's also arriving this week! #lindeengineering #combilift #investment

Linde’s PyroCrack® technology handles the full spectrum of feedstocks. Its twin cell design allows independent cracking of different feedstocks in one furnace. Learn more about how #LindeEngineering can drive your cracker plant to higher #Efficiency. fal.cn/3tJ6a

With state-of-the-art digitalization and automation technologies for steam crackers, #LindeEngineering is adapting to the increasing demand for ethylene. Examples are the use of digital twins and automatic mode change. Learn more: fal.cn/3tsHu #SteamCracking

Something went wrong.

Something went wrong.

United States Trends

- 1. #WWERaw 57.7K posts

- 2. Purdy 24.6K posts

- 3. Panthers 33K posts

- 4. 49ers 33.8K posts

- 5. Mac Jones 4,593 posts

- 6. Penta 9,054 posts

- 7. Canales 12.3K posts

- 8. #KeepPounding 5,099 posts

- 9. #FTTB 4,710 posts

- 10. Gunther 13.5K posts

- 11. Niners 4,893 posts

- 12. Jaycee Horn 2,534 posts

- 13. #RawOnNetflix 2,090 posts

- 14. Ji'Ayir Brown 1,123 posts

- 15. Melo 18.2K posts

- 16. #CARvsSF 1,189 posts

- 17. Rico Dowdle 1,496 posts

- 18. Mark Kelly 169K posts

- 19. McMillan 2,501 posts

- 20. Kittle 3,356 posts