#msizer search results

#Limestone fines tend to agglomerate, hold moisture unevenly, and compact under storage or transport. This makes the first screening stage an essential step in maintaining usable quality. The #MSizer SEL optimizes this process. bit.ly/4nDzSsq #screeningaccuracy

In feed manufacturing, every stage depends on how material behaves in motion at intake, before grinding and after cooling. The MSizer delivers all three stages within a compact footprint. bit.ly/47e0xal #feedprocessing #screeningtechnology #msizer

When #bulkmaterial meets resistance, it’s often the first screen’s oversight. In modular plants, the first #screening stage establishes principle. A setup built around the #MSizer SEL and a TMS vibrating distributor manages flow control upstream. bit.ly/3JjAjdH

At the back of the #MSizer lies the key to its motion, the drive configuration that dictates the trajectory of each particle that enters the screen. Every component in this very detailed layout informs the effectiveness of the material #separationprocess. bit.ly/4oiSwGK

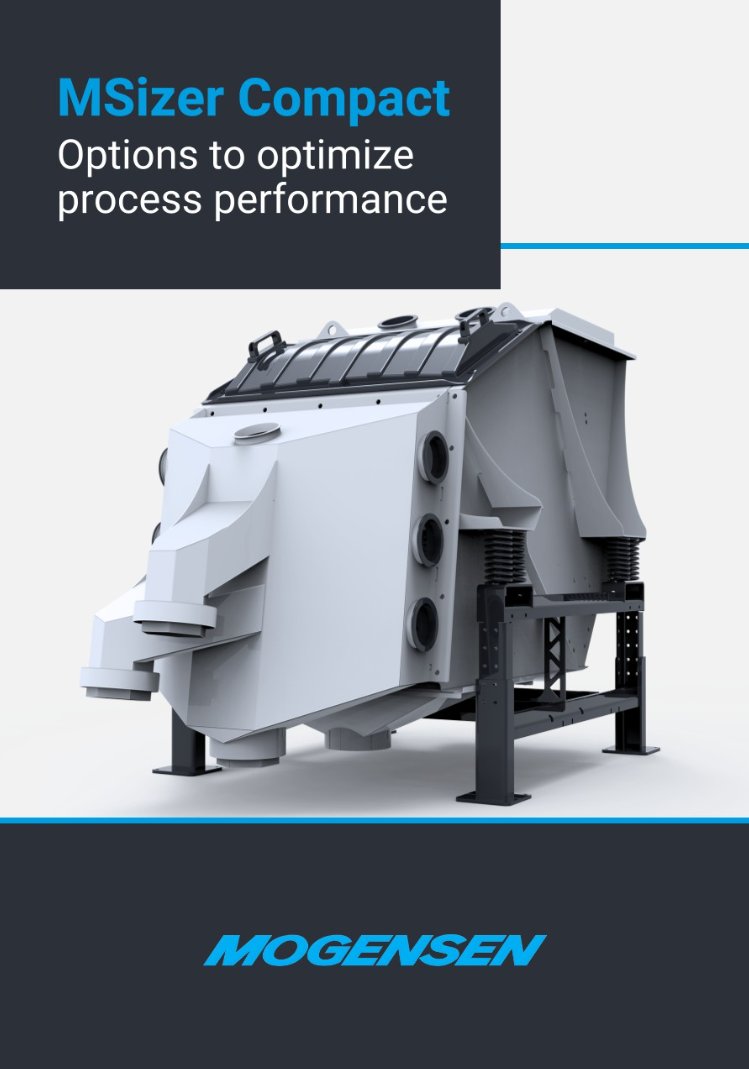

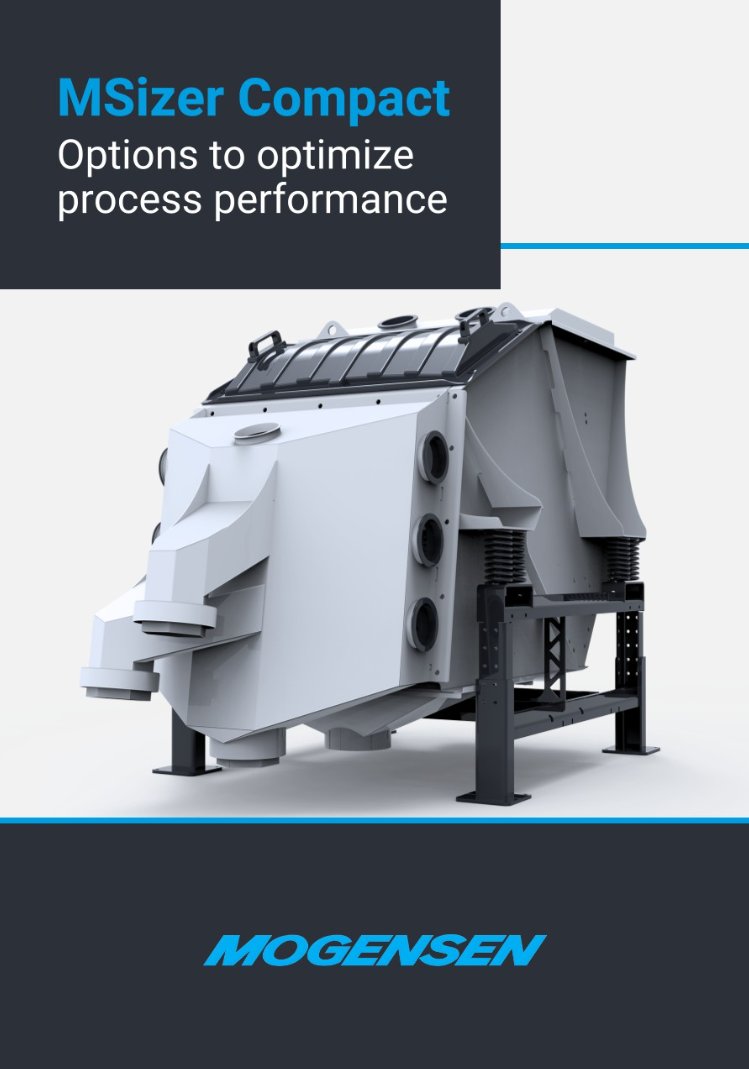

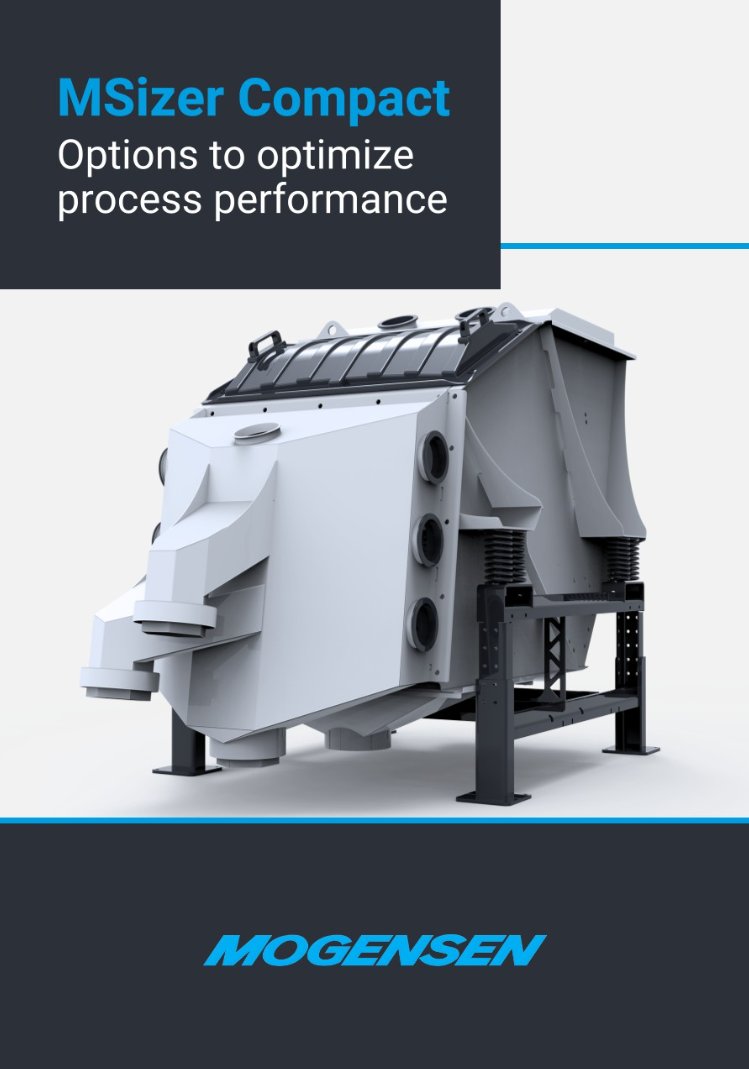

Where would we be without options? Options give both life and engineering their flexibility. The #MSizer Compact is a framework that evolves with experiences. bit.ly/3IaE1ph #screeningtechnology #processdesign

When designing an MSizer, we explore carefully how deck inclination, vibration pattern, and mesh opening interact with the specific limestone’s behavior. linkedin.com/feed/update/ur… #msizer #limestone #processtechnology

Expanded #clay begins as ordinary clay fired until it swells into porous, lightweight granules. Its value is in the air it holds; air that must remain intact for the material to fulfil its purpose. #Screening therefore becomes an act of balance. bit.ly/41ZNAxY #msizer

Sand is everywhere, though getting it just right for industrial use is a meticulous process. #Sandwashing efficiency comes down to how the material is presented to water and how quickly it leaves it again. That depends on #screening. bit.ly/3Jbwzuw #msizer

In detail: The drive behind the deck. The back of the MSizer reveals what remains at the core of its performance: intentionally designed motion, angle, and material flow. bit.ly/3YLNqbY #screeningtechnology #bulkmaterialhandling #msizer

Each dolomite #processing stage affects the material, but the #screening stage dictates future behaviour. The particle size distributing resulting from screening determines how reliably the material will melt, dissolve, or react. bit.ly/4o3gYMZ #msizer

At Mogensen, we approach aggregate sizing as a controlled, repeatable process that gives producers the ability to create precise concrete mixes designed to meet specific project requirements. bit.ly/4cRo7Lt #constructionindustry #msizer #screeningtechnology

In underground #saltmining, every square foot counts, and so does every millimeter of particle size. Consistent particle size supports product specifications and reinforces stability. That’s where the #MSizer proves its value. bit.ly/4337asX #saltindustry

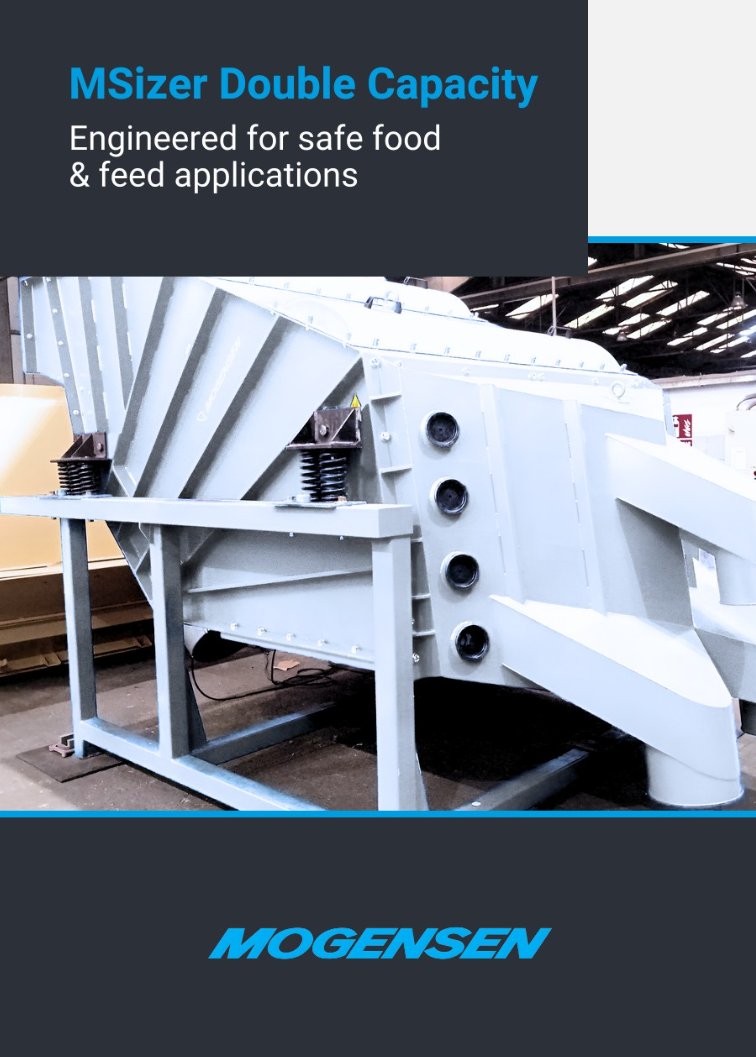

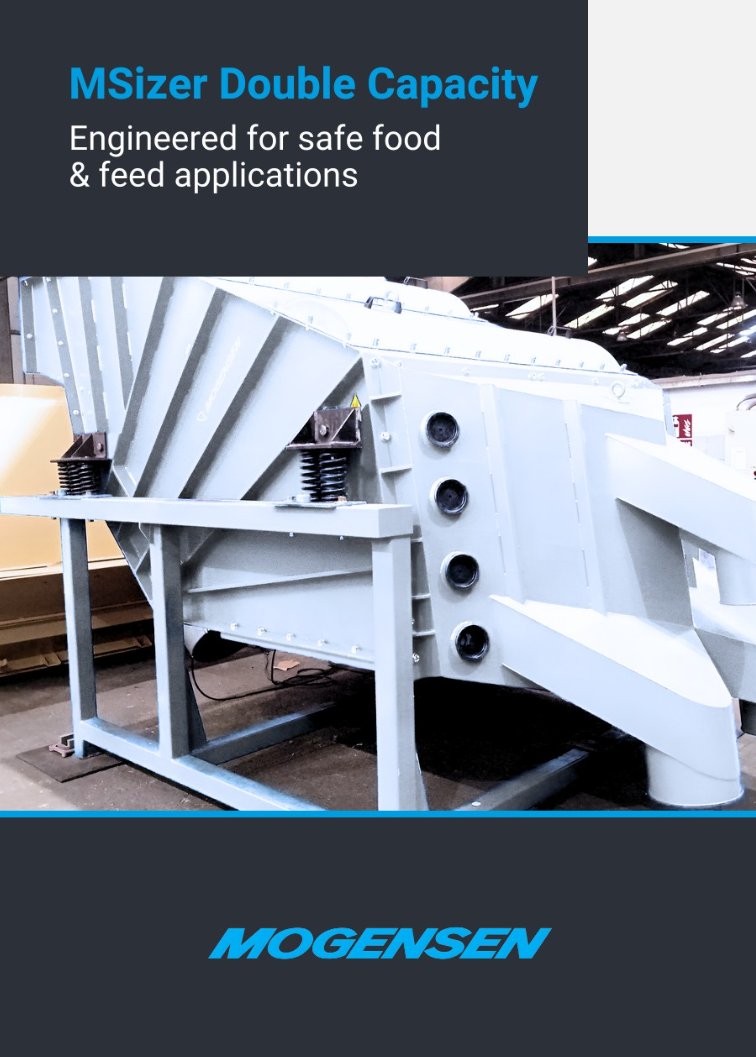

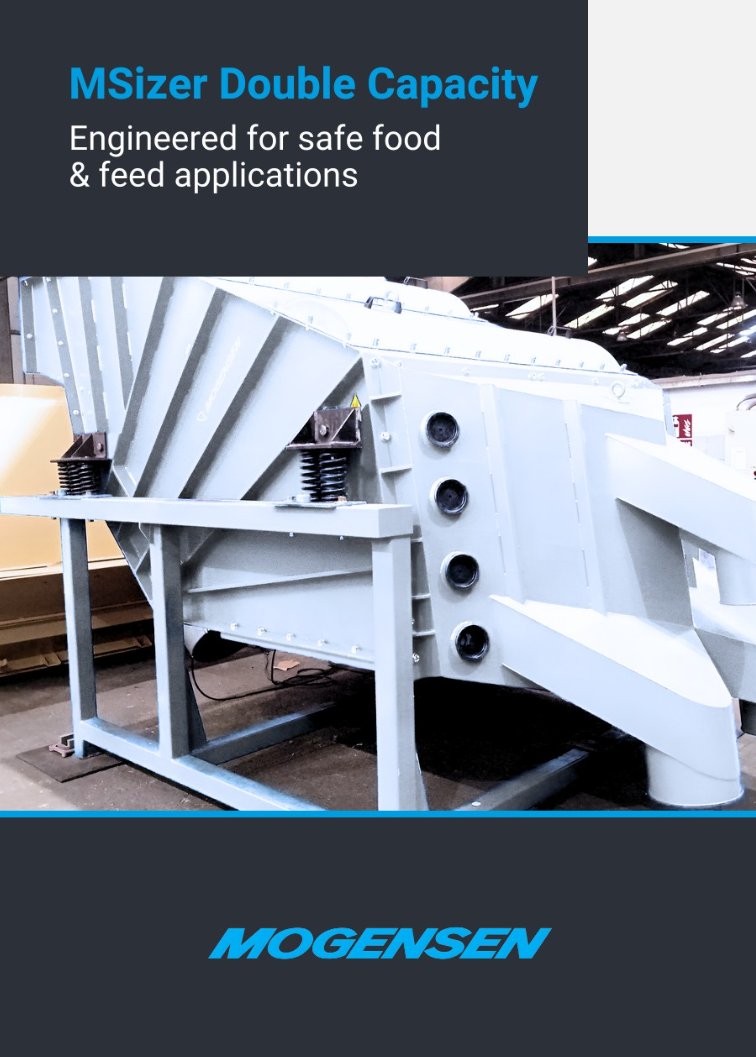

In food and #feedprocessing, what goes unseen also counts. From offloading to storage, even the smallest particle plays a role in the #quality of what we consume. That's where the #MSizer Double Capacity comes in. bit.ly/4ibLVL3

Thinking big and small: #Screeningequipment for every industrial need. In #industrialprocessing, both size and functionality count. The #MSizer family features versatile solutions designed to fit a variety of operating and space conditions. bit.ly/3R0pWeG

Sand is rarely just sand. In glassworks, casting molds, or precision mortars, it's a material that's evaluated grain by grain. What flows through the system isn't just a bulk material-it's a specification. bit.ly/4lXyX6P #sandwashing #processtechnology #msizer

Precision screening at full scale: the #MSizer Double Capacity. Bulk #materialprocessing demands both volume and vigilance. In food and feed, #screeningsystems must handle throughput without losing touch with detail. bit.ly/3T6vZQ1

Screening that respects the flow of #feedproduction. 🌾 In modern feed processing, each stage gains from accurate separation.The #MSizer adapts to the material. The result is steady throughput, lower wear and consistent #productquality. bit.ly/3SBmNTm

Screening high-friction materials without #processfatigue. With elliptical or linear oscillation tailored to each model, #MSizer units maintain precise #separation across a wide cut range, even as feed fluctuates in volume, texture, or density. bit.ly/3FhKOMp

High-volume screening can be viewed as a matter of raw throughput. However, in the food and #feedindustries, where even the smallest foreign particle can halt a batch, scale cannot come at the expense of sensitivity. bit.ly/41LqL0L #msizer #doublecapacity

When #bulkmaterial meets resistance, it’s often the first screen’s oversight. In modular plants, the first #screening stage establishes principle. A setup built around the #MSizer SEL and a TMS vibrating distributor manages flow control upstream. bit.ly/3JjAjdH

#Limestone fines tend to agglomerate, hold moisture unevenly, and compact under storage or transport. This makes the first screening stage an essential step in maintaining usable quality. The #MSizer SEL optimizes this process. bit.ly/4nDzSsq #screeningaccuracy

At the back of the #MSizer lies the key to its motion, the drive configuration that dictates the trajectory of each particle that enters the screen. Every component in this very detailed layout informs the effectiveness of the material #separationprocess. bit.ly/4oiSwGK

Sand is everywhere, though getting it just right for industrial use is a meticulous process. #Sandwashing efficiency comes down to how the material is presented to water and how quickly it leaves it again. That depends on #screening. bit.ly/3Jbwzuw #msizer

Each dolomite #processing stage affects the material, but the #screening stage dictates future behaviour. The particle size distributing resulting from screening determines how reliably the material will melt, dissolve, or react. bit.ly/4o3gYMZ #msizer

In feed manufacturing, every stage depends on how material behaves in motion at intake, before grinding and after cooling. The MSizer delivers all three stages within a compact footprint. bit.ly/47e0xal #feedprocessing #screeningtechnology #msizer

Expanded #clay begins as ordinary clay fired until it swells into porous, lightweight granules. Its value is in the air it holds; air that must remain intact for the material to fulfil its purpose. #Screening therefore becomes an act of balance. bit.ly/41ZNAxY #msizer

Where would we be without options? Options give both life and engineering their flexibility. The #MSizer Compact is a framework that evolves with experiences. bit.ly/3IaE1ph #screeningtechnology #processdesign

When designing an MSizer, we explore carefully how deck inclination, vibration pattern, and mesh opening interact with the specific limestone’s behavior. linkedin.com/feed/update/ur… #msizer #limestone #processtechnology

High-volume screening can be viewed as a matter of raw throughput. However, in the food and #feedindustries, where even the smallest foreign particle can halt a batch, scale cannot come at the expense of sensitivity. bit.ly/41LqL0L #msizer #doublecapacity

The #MSizer Compact, Extend, Giant, and Double Capacity may differ in scale, deck length, and drive configuration, yet each applies the same sizer #principle originally designed to turn chaotic particle flow into an ordered, predictable #process. bit.ly/45PhJ5m

Few materials are as surprisingly simple as salt. It flows easily, looks clean, and can be processed at high volumes. However, every ton comes with a mechanical cost. In this context, #screening becomes preservation. bit.ly/3Ha2zOA #MSizer #saltprocessing

Fine salt, near-dry, flows rapidly across screens. Yet consistent separation of coarse and fine fractions, especially under recycled or seasonal feed conditions, calls for more than just throughput. bit.ly/4k8vYpZ #saltprocessing #bulkhandling #msizer

Precision screening at full scale: the #MSizer Double Capacity. Bulk #materialprocessing demands both volume and vigilance. In food and feed, #screeningsystems must handle throughput without losing touch with detail. bit.ly/3T6vZQ1

Screening high-friction materials without #processfatigue. With elliptical or linear oscillation tailored to each model, #MSizer units maintain precise #separation across a wide cut range, even as feed fluctuates in volume, texture, or density. bit.ly/3FhKOMp

In detail: The drive behind the deck. The back of the MSizer reveals what remains at the core of its performance: intentionally designed motion, angle, and material flow. bit.ly/3YLNqbY #screeningtechnology #bulkmaterialhandling #msizer

Screening that respects the flow of #feedproduction. 🌾 In modern feed processing, each stage gains from accurate separation.The #MSizer adapts to the material. The result is steady throughput, lower wear and consistent #productquality. bit.ly/3SBmNTm

In underground #saltmining, every square foot counts, and so does every millimeter of particle size. Consistent particle size supports product specifications and reinforces stability. That’s where the #MSizer proves its value. bit.ly/4337asX #saltindustry

Sand is rarely just sand. In glassworks, casting molds, or precision mortars, it's a material that's evaluated grain by grain. What flows through the system isn't just a bulk material-it's a specification. bit.ly/4lXyX6P #sandwashing #processtechnology #msizer

At Mogensen, we approach aggregate sizing as a controlled, repeatable process that gives producers the ability to create precise concrete mixes designed to meet specific project requirements. bit.ly/4cRo7Lt #constructionindustry #msizer #screeningtechnology

In feed manufacturing, every stage depends on how material behaves in motion at intake, before grinding and after cooling. The MSizer delivers all three stages within a compact footprint. bit.ly/47e0xal #feedprocessing #screeningtechnology #msizer

Where would we be without options? Options give both life and engineering their flexibility. The #MSizer Compact is a framework that evolves with experiences. bit.ly/3IaE1ph #screeningtechnology #processdesign

When #bulkmaterial meets resistance, it’s often the first screen’s oversight. In modular plants, the first #screening stage establishes principle. A setup built around the #MSizer SEL and a TMS vibrating distributor manages flow control upstream. bit.ly/3JjAjdH

At the back of the #MSizer lies the key to its motion, the drive configuration that dictates the trajectory of each particle that enters the screen. Every component in this very detailed layout informs the effectiveness of the material #separationprocess. bit.ly/4oiSwGK

When designing an MSizer, we explore carefully how deck inclination, vibration pattern, and mesh opening interact with the specific limestone’s behavior. linkedin.com/feed/update/ur… #msizer #limestone #processtechnology

Sand is everywhere, though getting it just right for industrial use is a meticulous process. #Sandwashing efficiency comes down to how the material is presented to water and how quickly it leaves it again. That depends on #screening. bit.ly/3Jbwzuw #msizer

#Limestone fines tend to agglomerate, hold moisture unevenly, and compact under storage or transport. This makes the first screening stage an essential step in maintaining usable quality. The #MSizer SEL optimizes this process. bit.ly/4nDzSsq #screeningaccuracy

Each dolomite #processing stage affects the material, but the #screening stage dictates future behaviour. The particle size distributing resulting from screening determines how reliably the material will melt, dissolve, or react. bit.ly/4o3gYMZ #msizer

Adaptability defines the performance of #industrialprocessing technology. Our portfolio, from the almond shell-specific #MSizer to the biostabilized compost-tailored #GSort, represents a unique combination of engineering and application. bit.ly/42ADt3G

Expanded #clay begins as ordinary clay fired until it swells into porous, lightweight granules. Its value is in the air it holds; air that must remain intact for the material to fulfil its purpose. #Screening therefore becomes an act of balance. bit.ly/41ZNAxY #msizer

In detail: The drive behind the deck. The back of the MSizer reveals what remains at the core of its performance: intentionally designed motion, angle, and material flow. bit.ly/3YLNqbY #screeningtechnology #bulkmaterialhandling #msizer

Alumina's industrial versatility comes from its adaptability to multiple manufacturing requirements, making it a basic material in industries such as electronics, aerospace, and ceramics. bit.ly/3ENH9VP #aluminaprocessing #msizer #materialengineering

Thinking big and small: #Screeningequipment for every industrial need. In #industrialprocessing, both size and functionality count. The #MSizer family features versatile solutions designed to fit a variety of operating and space conditions. bit.ly/3R0pWeG

In food and #feedprocessing, what goes unseen also counts. From offloading to storage, even the smallest particle plays a role in the #quality of what we consume. That's where the #MSizer Double Capacity comes in. bit.ly/4ibLVL3

Sand is rarely just sand. In glassworks, casting molds, or precision mortars, it's a material that's evaluated grain by grain. What flows through the system isn't just a bulk material-it's a specification. bit.ly/4lXyX6P #sandwashing #processtechnology #msizer

Screening that respects the flow of #feedproduction. 🌾 In modern feed processing, each stage gains from accurate separation.The #MSizer adapts to the material. The result is steady throughput, lower wear and consistent #productquality. bit.ly/3SBmNTm

Precision screening at full scale: the #MSizer Double Capacity. Bulk #materialprocessing demands both volume and vigilance. In food and feed, #screeningsystems must handle throughput without losing touch with detail. bit.ly/3T6vZQ1

Screening high-friction materials without #processfatigue. With elliptical or linear oscillation tailored to each model, #MSizer units maintain precise #separation across a wide cut range, even as feed fluctuates in volume, texture, or density. bit.ly/3FhKOMp

Fine salt, near-dry, flows rapidly across screens. Yet consistent separation of coarse and fine fractions, especially under recycled or seasonal feed conditions, calls for more than just throughput. bit.ly/4k8vYpZ #saltprocessing #bulkhandling #msizer

Few materials are as surprisingly simple as salt. It flows easily, looks clean, and can be processed at high volumes. However, every ton comes with a mechanical cost. In this context, #screening becomes preservation. bit.ly/3Ha2zOA #MSizer #saltprocessing

Something went wrong.

Something went wrong.

United States Trends

- 1. Raindotgg N/A

- 2. Louisville 13.8K posts

- 3. Ortiz 15.2K posts

- 4. Nuss 5,515 posts

- 5. Miller Moss 1,113 posts

- 6. Bama 13.2K posts

- 7. UCLA 6,853 posts

- 8. #GoAvsGo 1,131 posts

- 9. Emmett Johnson 1,215 posts

- 10. Brohm 1,071 posts

- 11. #Huskers N/A

- 12. Ty Simpson 3,395 posts

- 13. The ACC 19.7K posts

- 14. Clemson 6,501 posts

- 15. Nikki Glaser N/A

- 16. #AEWCollision 9,706 posts

- 17. #RockHall2025 5,734 posts

- 18. Kentucky 29.9K posts

- 19. Lagway 3,564 posts

- 20. Stoops 2,043 posts