#postpro3d search results

The force is strong with #PostPro! Our resell partner, @3DPC_ printed this baby yoda on an FDM printer then vapour smoothed with #PostPro3D.

We have successfully integrated the automated turnkey #PostPro3D into our workflows. The addition of this unique #technology has helped #Jawstec3d create better products faster for our clients. jawstec.com/how-vapor-poli…

The #AdditiveMfg market is moving swiftly thanks to advancements in #3Dprinting. But adoption at scale will require a concerted focus on post processing. @addmantech worked with UL to help ensure the #PostPro3D meets #safety standards: s.ul.com/2C5Xp0A #CES2019

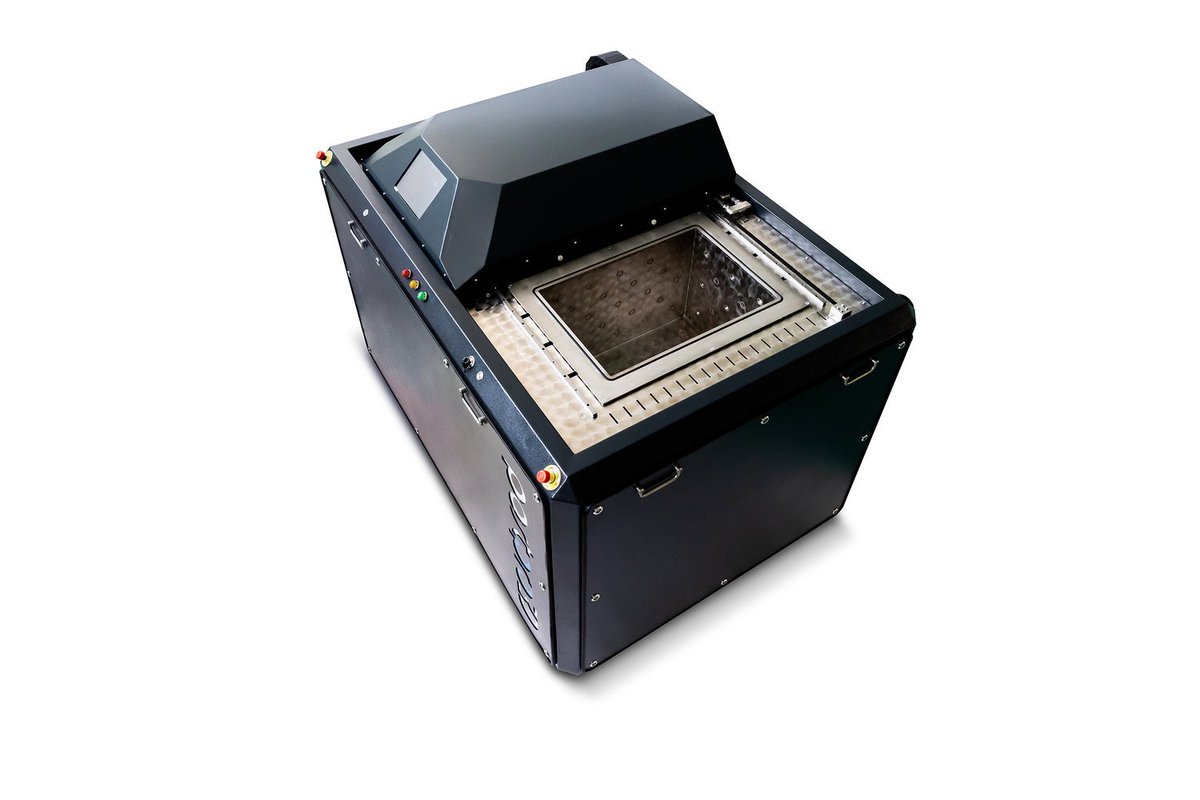

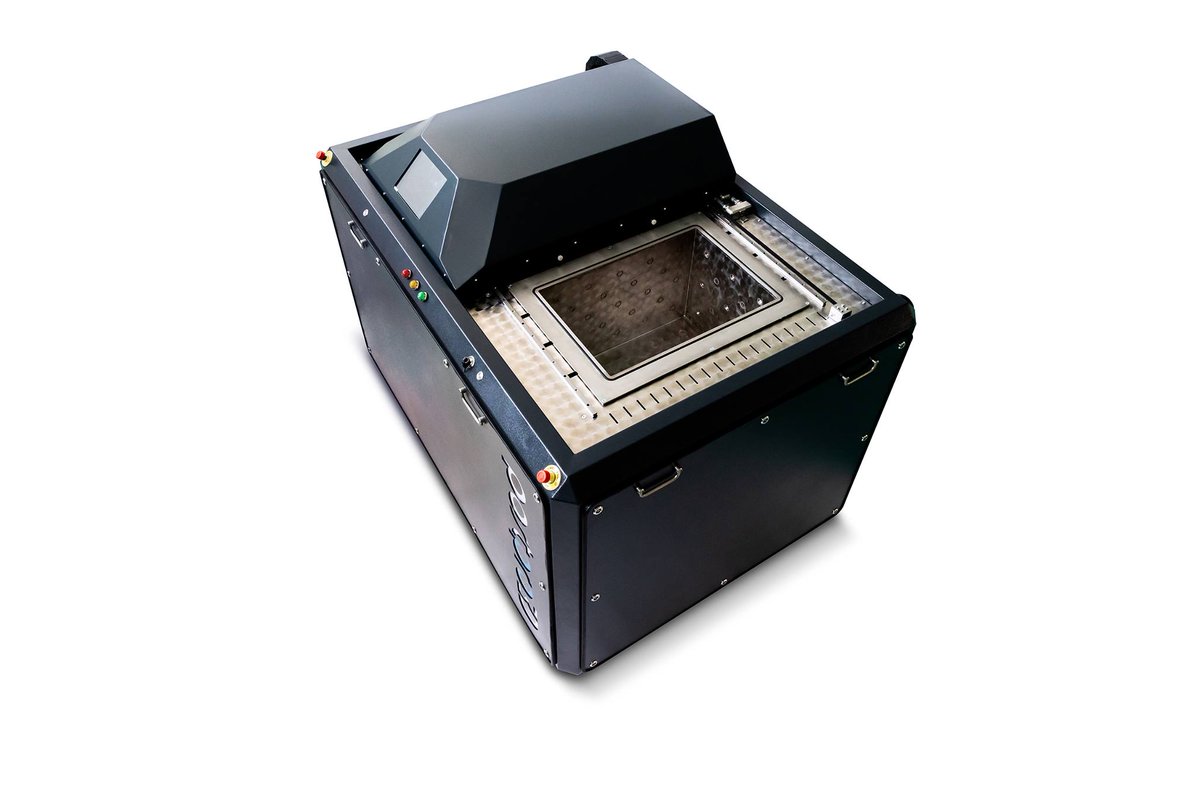

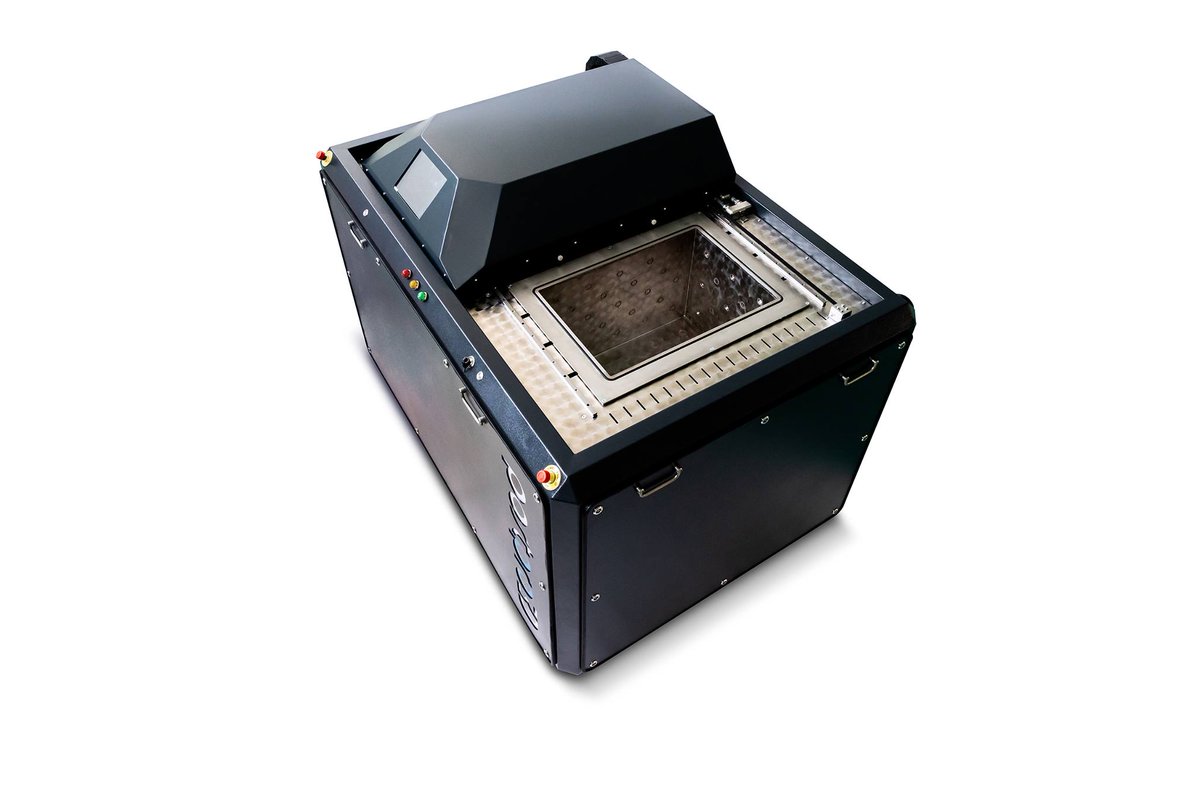

AMT's #PostPro3D is delivered with everything you need to get the machine up and running from Day 1 of the installation. The #PostPro3D is compatible with over 100 #thermoplastic #materials, and all #powder-bed and #filament-based #3Dprinting technologies. #AM #PostProcessing

AMT's #PostPro3DMini is illuminated in green, in honor of #StPatricksDay! The PostPro3DMini has all the advantages of the #PostPro3D, but in a more compact unit designed for smaller #production runs. Ideal for R&D departments, Universities & small service bureaus. #PostProcessing

Our AMT #Postpro3d Vapor Polish machine arrived this week. Who’s ready to order some awesome parts? Get your instant online quote today. jawstec.com #3dprinting #jawstec3d #additivemanufacturing #vaporpolish

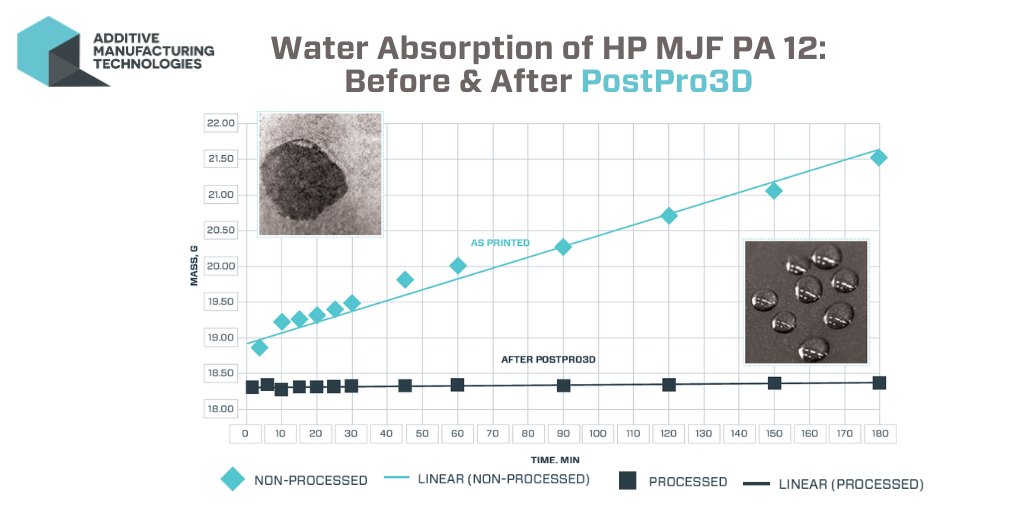

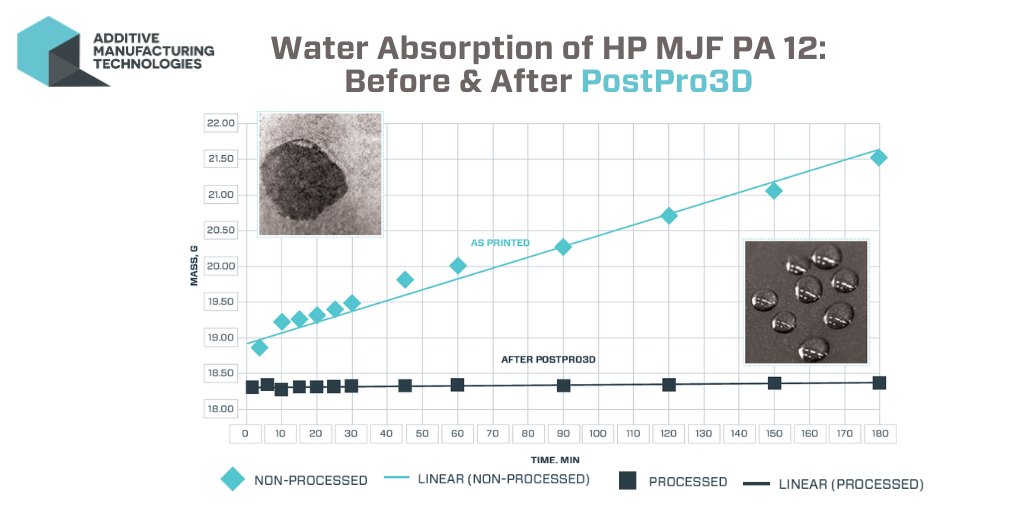

This test visibly illustrates how AMT’s #PostPro3D is able to completely #seal the surface of #polymer #3Dprinted parts, which is vital for many critical #AM production components. Send us your parts for benchmarking to see the results yourself: amtechnologies.com/contact/benchm… #3DP

In 2017, AMT solved the major bottleneck of manual #postprocessing by developing the world's first fully automated #ChemicalVaporSmoothing system, #PostPro3D. Three years and 2,312 production runs later, @MidwestProto is using this machine, among the rest of their #PostPro fleet.

Aesthetics aside, a major benefit of vapor smoothing #3Dprinted parts is the elimination in water absorption. By sealing the surface of the part with AMT’s #PostPro3D, water is deflected and does not penetrate over time compared to as-printed parts. amtechnologies.com/resources/down…

AMT USA has added @impacsys as first value added reseller in southern states. Impac Systems Engineering is an authorized reseller of various #3Dprinting technologies, and has now adopted AMT's #PostPro3D. Learn more about the new partnership: amtonline.org/article_displa…

3Dプリント部品の表面を自動的に滑らかにするマシン発売 idarts.co.jp/3dp/automated-… @idarts_jp #3Dprinting #3Dプリンタ #PostPro3D #3Dプリンティング #仕上加工 #後処理

Additive3D Asia and AMT announce strategic partnership in order to bring end-to-end AM solutions to Singapore, tackling the existing #3DPrinting post-processing gaps. Read on to find out more: bit.ly/3pGA78V #additivemanufacturing #PostPro3D #Innovations

Guess what arrived? Our new #PostPro3D #postprocessing solution from @amtpostpro! Can't wait to hear how much our customers like the mechanical and aesthetic enhancements to their #3Dprinted #polymer parts! ow.ly/muOl50AhW7e #additivemanufacturing #3Dprinting

Many thanks to #JosephCrabtree at #AMT for showcasing our vision for racing helmets! #PostPro3d #kupol3dhelmet lnkd.in/ebA3DhJ

Visitors of @formnext_expo will have the chance to witness live demonstrations of the brand new, innovative #PostPro3D solution. #AdditiveManufacturing maschinenmarkt.international/additive-manuf…

Congratulations @amtpostpro for gaining patent protection in the UK! Next up Europe and U.S. patents for the chemical vapor smoothing technology. Our customers are loving the look and performance of their #PostPro3D smoothed #HPMJF parts! ow.ly/qjjg50AwWoz

The force is strong with #PostPro! Our resell partner, @3DPC_ printed this baby yoda on an FDM printer then vapour smoothed with #PostPro3D.

The #AdditiveMfg market is moving swiftly thanks to advancements in #3Dprinting. But adoption at scale will require a concerted focus on post processing. @addmantech worked with UL to help ensure the #PostPro3D meets #safety standards: s.ul.com/2C5Xp0A #CES2019

We have successfully integrated the automated turnkey #PostPro3D into our workflows. The addition of this unique #technology has helped #Jawstec3d create better products faster for our clients. jawstec.com/how-vapor-poli…

AMT's #PostPro3DMini is illuminated in green, in honor of #StPatricksDay! The PostPro3DMini has all the advantages of the #PostPro3D, but in a more compact unit designed for smaller #production runs. Ideal for R&D departments, Universities & small service bureaus. #PostProcessing

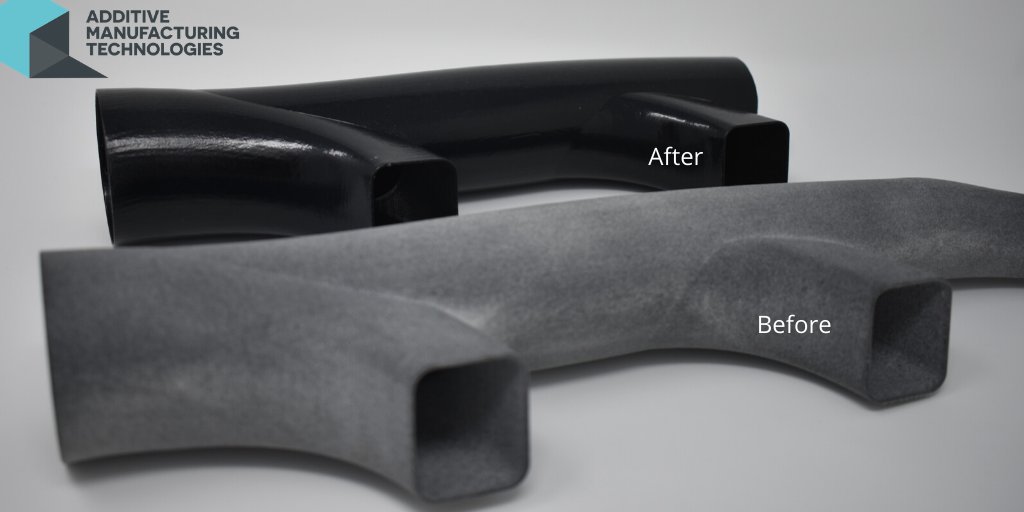

AMT’s #PostPro3D completely #smooths & #seals the surface and internal cavitities of #3Dprinted #polymer parts. Check out the #surfacefinish on this @BASF #TPU part. Have questions about AMT’s #automated #postprocessing solutions? Contact [email protected] for more info.

AMT’s #PostPro3D will be on display at @ManufacturingW1 Japan, Feb 26-28th. Our partner #3DPrintingCorporation will demonstrate #3Dprinting solutions from #designing to #postprocessing for mass production. Stop by Booth #50-46 in Hall 9 to learn more! #DMSJapan2020 #AM #3DP

In 2017, AMT solved the major bottleneck of manual #postprocessing by developing the world's first fully automated #ChemicalVaporSmoothing system, #PostPro3D. Three years and 2,312 production runs later, @MidwestProto is using this machine, among the rest of their #PostPro fleet.

Our AMT #Postpro3d Vapor Polish machine arrived this week. Who’s ready to order some awesome parts? Get your instant online quote today. jawstec.com #3dprinting #jawstec3d #additivemanufacturing #vaporpolish

Aesthetics aside, a major benefit of vapor smoothing #3Dprinted parts is the elimination in water absorption. By sealing the surface of the part with AMT’s #PostPro3D, water is deflected and does not penetrate over time compared to as-printed parts. amtechnologies.com/resources/down…

AMT’s fully #automated #PostPro3D completely #smooths & #seals the surface of #polymer #3Dprinted parts, equivalent to that of an #injectionmolded part. Want to see it for yourself? Send us your parts for benchmarking! Learn more: amtechnologies.com/benchmarking.h…

AMT USA has added @impacsys as first value added reseller in southern states. Impac Systems Engineering is an authorized reseller of various #3Dprinting technologies, and has now adopted AMT's #PostPro3D. Learn more about the new partnership: amtonline.org/article_displa…

Additive3D Asia and AMT announce strategic partnership in order to bring end-to-end AM solutions to Singapore, tackling the existing #3DPrinting post-processing gaps. Read on to find out more: bit.ly/3pGA78V #additivemanufacturing #PostPro3D #Innovations

Guess what arrived? Our new #PostPro3D #postprocessing solution from @amtpostpro! Can't wait to hear how much our customers like the mechanical and aesthetic enhancements to their #3Dprinted #polymer parts! ow.ly/muOl50AhW7e #additivemanufacturing #3Dprinting

Something went wrong.

Something went wrong.

United States Trends

- 1. #GMMTV2026 3.7M posts

- 2. Good Tuesday 34.6K posts

- 3. MILKLOVE BORN TO SHINE 554K posts

- 4. #NuestraBanderaEsBolívar 2,184 posts

- 5. #tuesdayvibe 2,621 posts

- 6. Taco Tuesday 12.2K posts

- 7. WILLIAMEST MAGIC VIBES 89K posts

- 8. Alan Dershowitz 3,977 posts

- 9. Happy Thanksgiving 17.9K posts

- 10. Mark Kelly 229K posts

- 11. Mainz Biomed N.V. N/A

- 12. University of Minnesota N/A

- 13. Praying for Pedro N/A

- 14. Enron 1,854 posts

- 15. Hegseth 107K posts

- 16. #25Nov 2,454 posts

- 17. #DittoSeries 104K posts

- 18. Naps 2,943 posts

- 19. Maddow 17.6K posts

- 20. JOSSGAWIN MAGIC VIBES 33.4K posts